Kyotechs E321D Cylinder Head - Optimum Durability & Performance

Kyotechs E321D Cylinder Head

high quality Performance and Durability

Introducing the Kyotechs E321D Cylinder Head, a product meticulously engineered for those who demand excellence and reliability in their machinery. Crafted using advanced technology, this cylinder head promises optimal performance and remarkable resilience, making it the ideal choice for your equipment.

The Kyotechs E321D Cylinder Head is built with high-quality materials, ensuring it can withstand extreme conditions and intensive usage while maintaining peak functionality. This product's precise engineering ensures seamless integration with your machinery, optimizing performance and extending the lifespan of your equipment.

Kyotechs is a brand synonymous with durability and trust, and the E321D Cylinder Head is a testament to our commitment to excellence. Each unit undergoes a rigorous quality assurance process, ensuring it meets the highest industry standards before reaching you.

Ease of installation is another highlight of the Kyotechs E321D Cylinder Head. Designed with user-friendliness in mind, you'll find the setup process straightforward, allowing you to minimize downtime and return to full operational efficiency swiftly.

Selecting the Kyotechs E321D Cylinder Head means choosing a product that is not only reliable but also backed by comprehensive customer support. Our dedicated team is always ready to offer assistance and ensure your experience with our product is nothing short of exceptional.

Make the smart choice with the Kyotechs E321D Cylinder Head—where durability, performance, and reliability converge to fuel your machine’s success.

Picture Show

Advantages

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

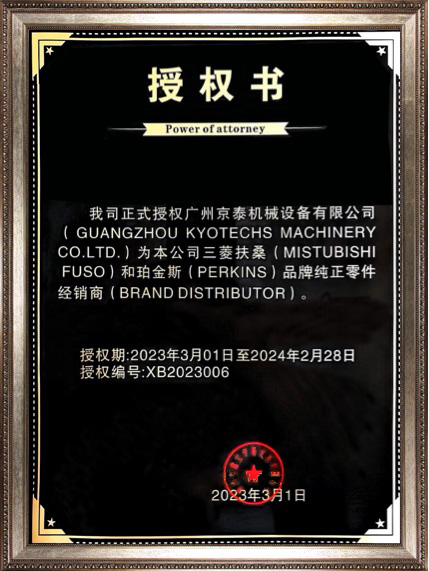

Certificate display

SANY Power

HANDOK Hydraulic

Perkins

Question you may concern

What are the common causes of failure of hydraulic pump control valves?

Common causes of control valve failure include internal wear, seal damage, contamination and valve blockage.

What are the best practices for hydraulic pump system maintenance?

Best practices include regular inspection and replacement of hydraulic oil and filters, keeping the system clean, regular inspection and tightening of all connections, and monitoring system pressure and temperature.

What liquid should be added to the battery (battery) used normally in the excavator after the liquid level drops? Why?

Distilled water should be added. Because the battery will generate heat during the charging and discharging process, the water will evaporate, and the specific gravity of the electrolyte will increase. After adding distilled water, the specific gravity of the electrolyte can be restored.

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

If you have any questions or concern, please contact us.

Excavator Spare Parts 2977644 Cylinder Head For Caterpillar E320D

Excavator Spare Parts 708-1W-01310 Hydraulic Main Pump For Komatsu PC75R-2

Excavator Spare Parts VH241004631A Turbochager For Kobelco SK200-8

Excavator Spare Parts PSVD2-17E-19 Hydraulic Pump For YANMAR VIO55

Excavator Parts SAA6D125E-3 Engine Assembly For Komatsu PC400-7

Excavator Spare Parts 4606144 Control Valve For Hitachi ZX200-3

Excavator Spare Parts 4254137 Control Valve For Hitachi ZX330-3 ZX350-3

Excavator Spare Parts 723-47-27503 Control Valve For Komatsu PC400-7

Discover the Kyotechs 723-47-27503 Control Valve, designed specifically for Komatsu models PC400-7, PC400-8, PC450-8, and PC300-7. Enhance your excavator’s performance with our reliable, durable spare parts. Perfectly replacing 723-47-27501, it ensures optimal functionality and efficiency. Elevate your operations with Kyotechs quality today.

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs