Everything You Need to Know About the 1617E330D Swing Gearbox by Kyotechs

Introduction

Welcome to the ultimate guide on the 1617E330D swing gearbox by Kyotechs. In this comprehensive article, we will explore everything you need to know about this essential excavator part, including its features, benefits, compatibility, and where to purchase it. Whether you're a construction business owner, equipment operator, or simply passionate about heavy machinery, this article is designed to provide you with valuable insights into the 1617E330D swing gearbox.

What is the 1617E330D Swing Gearbox?

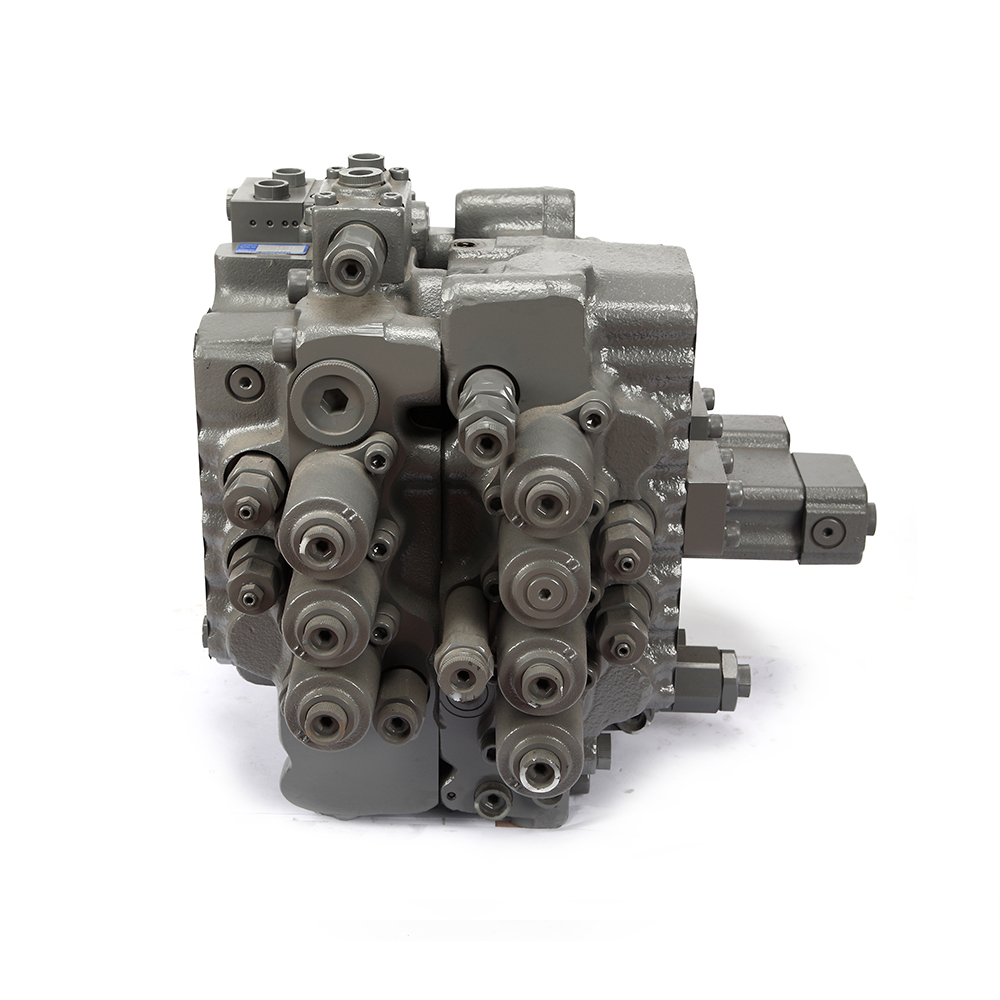

The 1617E330D swing gearbox is a crucial component of excavators, responsible for controlling the rotation of the machine's upper structure. This gearbox is designed to withstand heavy-duty usage, offering superior durability and performance for various excavator models. It plays a critical role in ensuring smooth and efficient operation, making it an indispensable part for construction and excavation projects.

Features and Benefits of the 1617E330D Swing Gearbox

Kyotechs' 1617E330D swing gearbox is engineered with precision and quality in mind, featuring high-strength materials and advanced technology. Its key features include exceptional load-bearing capacity, corrosion resistance, and precise gear engagement, resulting in optimal functionality and longevity. By choosing this gearbox, excavator owners can enjoy benefits such as enhanced productivity, reduced maintenance costs, and extended equipment lifespan.

Compatibility with Excavator Models

One of the standout qualities of the 1617E330D swing gearbox is its compatibility with a wide range of excavator models. Kyotechs ensures that this gearbox seamlessly fits popular brands such as Hitachi, Sany, Kawasaki, Volvo, Hyundai, Doosan, Komatsu, Caterpillar, Case, and Kobelco. This versatility allows construction professionals to acquire a reliable replacement or upgrade part for their specific excavator without compatibility concerns.

Where to Purchase the 1617E330D Swing Gearbox

Kyotechs, established in 2009, is a reputable supplier of excavator parts, offering a full range of high-quality products to meet diverse industry needs. From engine assemblies and hydraulic components to electric parts and undercarriage components, Kyotechs is a trusted source for top-notch construction equipment parts. As a leading provider of the 1617E330D swing gearbox, Kyotechs ensures availability, affordability, and exceptional customer service for all their products.

Conclusion

In conclusion, the 1617E330D swing gearbox by Kyotechs stands as a premium solution for excavator owners seeking reliability, performance, and compatibility. With its robust features, versatile compatibility, and trusted brand reputation, this gearbox is an essential addition to any construction equipment fleet. By choosing Kyotechs, businesses and individuals can access the best-in-class parts and components for their excavators, ensuring operational excellence and long-term value.

Unique FAQs

1. What makes the 1617E330D swing gearbox an ideal choice for excavator owners?

- The gearbox's exceptional load-bearing capacity, compatibility with various excavator models, and high-strength construction make it a standout choice for industry professionals.

2. Can I trust Kyotechs as a reliable supplier for the 1617E330D swing gearbox?

- Yes, Kyotechs has a strong track record of providing top-quality excavator parts, offering a guarantee of authenticity, performance, and customer satisfaction.

3. Is the 1617E330D swing gearbox suitable for both heavy-duty and light-duty excavation tasks?

- Absolutely, this gearbox is engineered to meet the demands of diverse excavation projects, ensuring consistent reliability and optimal performance.

4. How can I determine the compatibility of the 1617E330D swing gearbox with my specific excavator model?

- Kyotechs provides detailed compatibility information for their gearbox, enabling customers to verify the suitability of the part for their particular excavator model.

5. Can the 1617E330D swing gearbox be shipped internationally?

- Yes, Kyotechs offers international shipping services, making it convenient for customers worldwide to access their high-quality excavator parts.

Wholesale yanmar excavator parts manufacturer and supplier in Guangzhou

Kyotechs best professional Danfoss excavator parts Manufacturers and supplier brand

Kyotechs best professional Daewoo excavator parts Manufacturers and supplier brand

Wholesale yanmar excavator parts manufacturer and supplier in Guangzhou

FAQS

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

How to vent the hydraulic pump after installation?

The way to vent after installation is to slowly operate all functions of the hydraulic system until the air is exhausted, and check and maintain the hydraulic oil level during this process.

How do you pressure test a hydraulic pump?

Using a hydraulic pressure gauge connected to the pump's test port, operate the excavator to generate pressure and compare the reading to the manufacturer's specifications.

What is the maintenance frequency of the hydraulic pump?

The maintenance frequency of the hydraulic pump is usually performed every 1000 to 2000 hours of operation or once a year according to the manufacturer's recommendations.

What are the reasons why the excavator can rotate when starting, but cannot start?

1.There is no oil in the fuel tank.

2.The fuel filter and oil-water separator are blocked.

3.The low-pressure oil circuit does not supply oil.

4.The injection pump does not pump oil.

5.There is air in the oil circuit.

6.The valve timing is misaligned. The opening time of the valve is not coordinated with the stroke of the piston in the cylinder. For example, when the piston makes a compression stroke in the cylinder, the intake and exhaust valves are open, and fresh air is driven out of the cylinder, so that there is no combustion gas in the cylinder and it cannot start.

7.The solenoid valve of the injection pump is broken and is in a closed state, and the diesel cannot enter the high-pressure chamber.

Excavator Spare Parts 21N8-20505 Switch Membrane For Hyundai R210LC-7

Excavator Parts 31N6-25130 Solenoid Valve For Hyundai R160LC-7

Excavator Spare Parts YB60000571 Pilot Valve For Hitachi ZX60

Excavator Spare Parts 8-98197654-0 Front Shock Absorber For ISUZU

Excavator Spare Parts 14714208 Control Valve For Volvo EC220E

Excavator Parts 5659737 Hydraulic Pump For Caterpillar 336GC

Bulldozer Hydraulic Main Control Valve 723-63-24100 For Komatsu D65-15

D31 Bulldozer Hydraulic Pump Ass'y 720-2M-00031 For Komatsu D31EX-21

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs