How to Source Dismantled Excavator Parts for Your Next Project

The Importance of Quality Excavator Parts

1. Understanding the Benefits of Using Dismantled Excavator Parts

Sub1. Cost-Effective Solution

Sub2. Wide Range of Options

Sub3. Quality and Reliability

2. Essential Factors to Consider When Sourcing Excavator Parts

Sub1. Compatibility and Fit

Sub2. Quality Assurance and Warranty

Sub3. Reputation and Customer Reviews

3. Where to Source Dismantled Excavator Parts

Sub1. Authorized Dealers and Manufacturers

Sub2. Online Marketplaces and Auctions

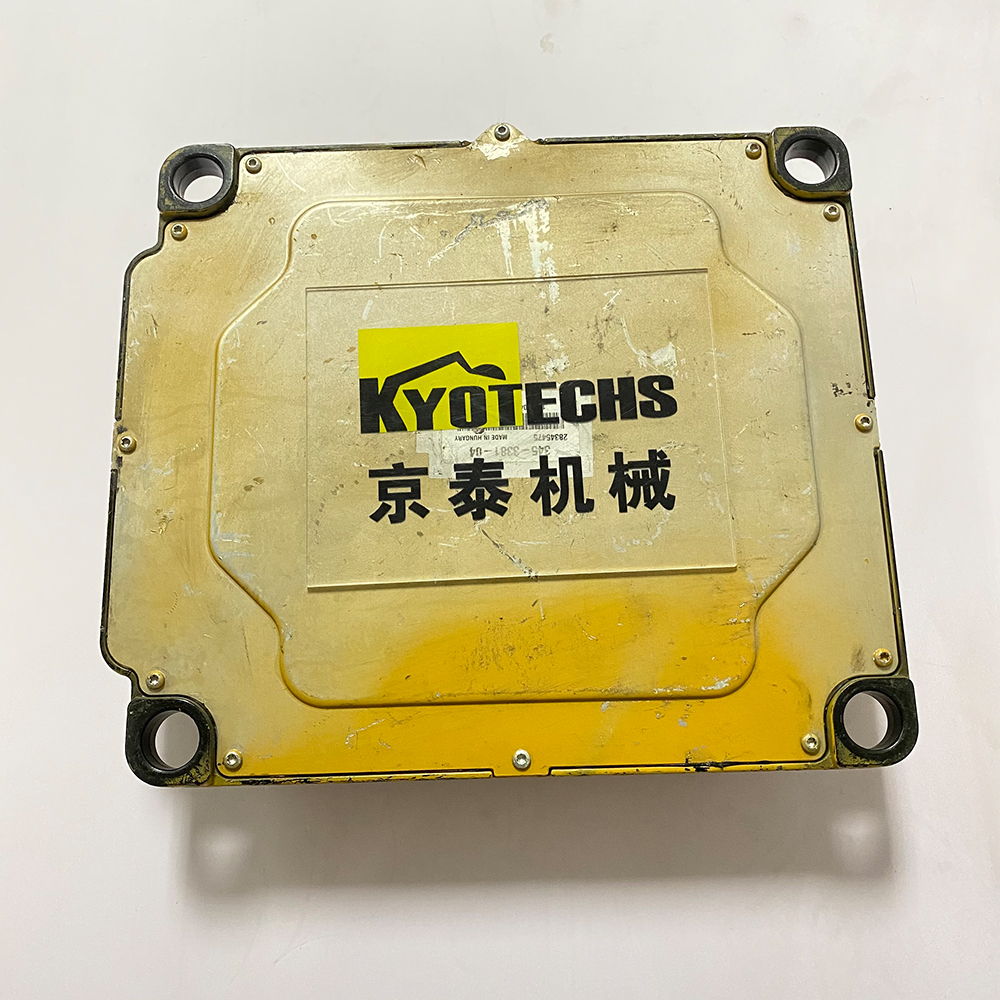

Sub3. Specialized Parts Suppliers like Kyotechs

4. How Kyotechs Can Help You Find the Right Excavator Parts

Sub1. Extensive Range of Parts for Various Excavator Brands

Sub2. Quality Assurance and Warranty

Sub3. Expert Technical Support and Guidance

5. Tips for Making Smart Purchases of Dismantled Excavator Parts

Sub1. Research the Seller and Product Background

Sub2. Verify Part Condition and Compatibility

Sub3. Take Advantage of Bulk Discounts and Special Offers

Conclusion: Ensuring the Longevity of Your Excavator with Quality Parts

As you can see, finding dismantled excavator parts doesn't have to be a daunting task. By following these tips and utilizing the expertise of Kyotechs, you can ensure that your excavator operates at its peak performance and delivers excellent results for your projects.

FAQs

Q1: Can I find dismantled excavator parts for older models?

A1: Yes, Kyotechs offers a wide range of parts for various excavator models, including older and discontinued ones.

Q2: How can I be sure of the quality of the dismantled parts?

A2: Kyotechs performs rigorous quality checks and offers warranties on all excavator parts to guarantee their performance and reliability.

Q3: Can I purchase dismantled excavator parts in bulk?

A3: Yes, Kyotechs offers bulk discounts and special offers for customers looking to purchase excavator parts in large quantities.

Q4: Do you provide technical support for installing the excavator parts?

A4: Yes, Kyotechs has a team of experts who can provide technical support and guidance for installing and using excavator parts.

Q5: How can I place an order for dismantled excavator parts?

A5: You can easily place an order for dismantled excavator parts through the Kyotechs website or by contacting their customer service team for assistance.

High-Quality Excavator Parts & Construction Equipment Solutions - Kyotechs

The Ultimate Guide to Finding Kato Excavator Parts in the USA

Wholesale yanmar excavator parts manufacturer and supplier in Guangzhou

Wholesale kubota excavator parts manufacturer and supplier in Guangzhou

FAQS

How to address overheating due to high ambient temperature?

Possible inadequate cooling or high oil viscosity.

Solution: Improve ventilation, use correct viscosity oil.

How to prevent hydraulic pump wear?

The way to prevent wear includes regular maintenance, using the right hydraulic oil, keeping the hydraulic system clean, and avoiding overload operation.

How to address travel system issues in an excavator?

Inspect the tracks, travel motors, and travel reducers. Test the pressure and flow of the hydraulic drive system, check if the control valves are functioning correctly, and perform necessary repairs or replacements.

How to check the coolant level of the excavator?

When the engine is cold, check the coolant level through the level gauge of the coolant tank and add coolant if necessary.

What does Kyotechs do?

Kyotechs specializes in providing a wide range of parts for excavators and heavy equipment, including hydraulic pumps, engine parts, electronic controllers, drivetrain components, travel gear, oil seals, filters, etc. They provide spare parts for many makes and models of excavators.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs