Yanmar Excavator Hydraulic Pump: Your Ultimate Guide to Maintenance and Replacement

Learn about Hydraulic Pump

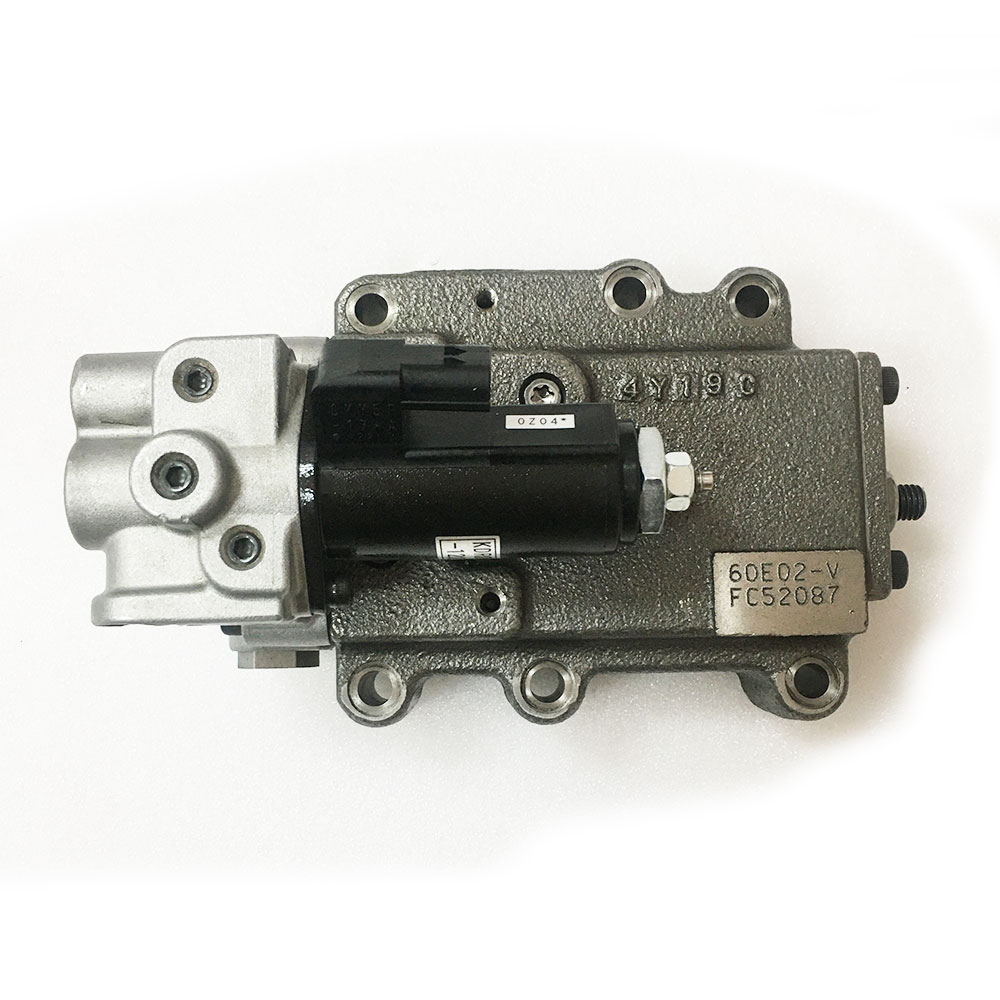

1. Introduction to Yanmar Excavator Hydraulic Pump Maintenance

Understanding the importance of proper maintenance

Common issues and signs of hydraulic pump problems

2. The Role of Hydraulic Pump in Yanmar Excavators

How the hydraulic pump works

importance of maintaining the hydraulic pump for overall excavator performance

3. Essential Maintenance Tips for Yanmar Excavator Hydraulic Pump

Regular inspection and cleaning

Checking for leaks and abnormal noises

Lubrication and fluid level checks

4. Replacement Options for Yanmar Excavator Hydraulic Pump

Signs that indicate the need for replacement

Choosing the right replacement parts

5. Expert Advice from Kyotechs for Yanmar Excavator Owners

Common maintenance mistakes to avoid

Benefits of using genuine parts and services

6. Kyotechs: Your Trusted Partner for Excavator Parts and Services

Company profile and expertise in providing excavator parts

Commitment to quality and customer satisfaction

7. Frequently Asked Questions about Yanmar Excavator Hydraulic Pump

How often should I inspect my hydraulic pump?

What are the signs of a failing hydraulic pump?

Can I replace the hydraulic pump on my own?

Why choose Kyotechs for replacement parts and services?

8. Conclusion

Recap the importance of proper maintenance and the role of Kyotechs in providing expert guidance and solutions.

Hydraulic pump FAQs:

1. How often should I inspect my hydraulic pump?

It is recommended to inspect your hydraulic pump every 500 operating hours or as per the manufacturer's guidelines.

2. What are the signs of a failing hydraulic pump?

Common signs include unusual noise, decreased performance, and fluid leaks. If you notice any of these signs, it may be time for a replacement.

3. Can I replace the hydraulic pump on my own?

While it is possible, it is highly recommended to seek professional assistance to ensure proper installation and compatibility with your Yanmar excavator.

4. Why choose Kyotechs for replacement parts and services?

Kyotechs offers a full range of genuine parts for excavators, including the Yanmar hydraulic pump. With our expertise and commitment to quality, you can trust us to provide reliable solutions for your excavator needs.

Kyotechs best professional Volvo excavator parts Manufacturers and supplier brand

Kyotechs best professional kato excavator parts Manufacturers and supplier brand

Enhance Your Travel Experience with Kyotechs 1125E305 Travel Gearbox

Wholesale UCHIDA excavator parts manufacturer and supplier

FAQS

What to do if the excavator has an oil leak?

To address oil leaks, inspect seals, fittings, and lines. Locate the leak, tighten any loose fittings, and replace worn or damaged seals and lines. Clean the area and recheck for leaks.

How often should the hydraulic oil be changed?

Usually the hydraulic oil is changed every 2000 hours or as recommended by the manufacturer.

What are the reasons why the excavator can rotate when starting, but cannot start?

1.There is no oil in the fuel tank.

2.The fuel filter and oil-water separator are blocked.

3.The low-pressure oil circuit does not supply oil.

4.The injection pump does not pump oil.

5.There is air in the oil circuit.

6.The valve timing is misaligned. The opening time of the valve is not coordinated with the stroke of the piston in the cylinder. For example, when the piston makes a compression stroke in the cylinder, the intake and exhaust valves are open, and fresh air is driven out of the cylinder, so that there is no combustion gas in the cylinder and it cannot start.

7.The solenoid valve of the injection pump is broken and is in a closed state, and the diesel cannot enter the high-pressure chamber.

How do you diagnose a faulty fuel injector in an excavator engine?

To diagnose a faulty fuel injector, listen for any unusual engine noises or misfires. Perform a balance test to identify which injector is causing the problem. Use a diagnostic tool to check for fault codes related to the fuel system. If necessary, remove and inspect the injector for signs of clogging or damage, and replace it if needed.

What causes hydraulic pump cavitation?

Possible low hydraulic oil level, high oil viscosity, or restricted fluid flow.

Solution: Refill hydraulic oil, use correct viscosity oil, check and clear restricted areas.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs