1117CX135 Main Control Valve - Precision Control Technology

Introducing the 1117CX135 Main Control Valve, the latest advancement in precision control technology. This state-of-the-art valve is designed to meet the needs of industrial applications, providing unmatched performance and reliability.

With its innovative design and advanced features, the 1117CX135 Main Control Valve offers unparalleled precision and control. Its reliable operation ensures smooth and efficient performance, while its durable construction ensures long-lasting reliability. Whether you need to regulate fluid flow, pressure, or temperature, this valve delivers unmatched accuracy and consistency.

The 1117CX135 Main Control Valve is engineered to outperform the competition, offering superior control and efficiency. Its advanced technology allows for precise adjustments, ensuring optimal performance in any operating conditions. From industrial processes to manufacturing applications, this valve is the ideal choice for demanding control applications.

With its user-friendly design and easy installation, the 1117CX135 Main Control Valve is the perfect solution for any industrial control system. Its intuitive operation and simple maintenance make it easy to integrate into any existing system, providing seamless performance without any hassle. Plus, its compact size makes it easy to incorporate into any space-constrained environment.

In summary, the 1117CX135 Main Control Valve is the ultimate choice for precision control in industrial applications. Its advanced features, reliable performance, and user-friendly design make it the perfect solution for any control system.

Advantages

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

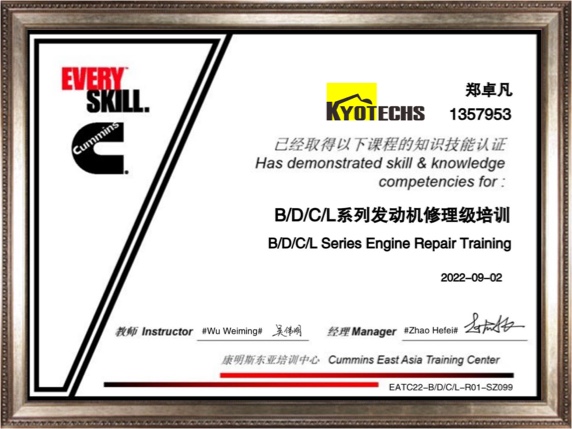

Certificate display

Cummins REPAIR TRAINING

HANDOK Hydraulic

Cummins BETT & INSITE

Q&A

When does the battery in use need to be recharged?

When the battery liquid specific gravity is lower than 1.15 or the single cell voltage is lower than 1.7V (V), or when changing seasons for maintenance, it should be removed for recharging and the liquid specific gravity should be adjusted. If it needs to be parked for a long time, it should be fully charged and stored, and recharged once a month. If it needs to be stored for a long time, it should be fully charged, all the liquid should be poured out, and the filling port should be sealed for storage. When it needs to be used, re-add the electrolyte that meets the requirements.

What is the matter with the engine speed drop when the excavator is working? How to solve it?

8 reasons for the engine speed drop of the excavator, 6 solutions are here!

As the name suggests, engine speed drop means the failure of the engine speed drop during the operation of the excavator. There are two manifestations of speed drop, one is a slight speed drop within 200 revolutions, and the other is a serious speed drop above 300 revolutions, which is likely to cause the excavator to suddenly shut down. There are 8 main reasons for the engine speed drop of the excavator.

1. The diesel oil circuit of the excavator is faulty. Generally speaking, when the diesel oil circuit is blocked, it may cause the speed drop phenomenon.

2. The hydraulic system of the excavator has a fault, so that the hydraulic pump cannot change the displacement normally, causing the system pressure to be too high, and the speed drop may also cause a machine failure.

3. The output power of the excavator engine itself is insufficient, the output power is lower than the rated power, and the speed is too low. There is also a problem with the main pump.

4. The engine uses fuel of poor quality or the water content of the fuel is too high, which will lead to insufficient engine power and speed drop.

5. When the air intake system leaks or is blocked, the engine will be short of air supply, resulting in incomplete combustion of fuel, and there will be speed drop and black smoke failure.

6. Due to the large gap of the solenoid valve, the fuel supply is insufficient, which causes the engine to drop.

7. The joint of the fuel supply circuit of the fuel system is loose or the pipeline is broken, causing fuel leakage or foreign matter blockage, resulting in insufficient fuel supply. In addition to speed drop, it may also cause flameout.

8. There are many reasons for speed drop, such as incorrect valve clearance, wrong injection timing, damaged turbocharger, faulty brakes, etc.

Having said so many reasons for the speed drop of the excavator engine, what should we do when the speed drop occurs?

The solutions are all here!

1. First, check whether the diesel used in the excavator is deteriorated, whether there are impurities in the oil, and whether the oil circuit is blocked.

2. Check the valve clearance of the excavator engine and the speed of the engine.

3. Check the intake pipeline, clean the air pre-filter and air filter element, and start the engine again.

4. Check whether the speed drop of the excavator occurs when the engine is under load?

5. Carefully check the engine to see if the engine failure causes the speed drop of the excavator engine.

6. In addition, the electronic control, hydraulic system, fuel system, etc. need to be checked.

How to replace the seal of a hydraulic pump?

The steps for replacing the seal are to stop the machine, release the system pressure, remove the pump, replace the seal, reinstall the pump and check the operation.

What steps should be taken if the excavator engine exhibits low oil pressure?

First, check the oil level and add oil if it's low. Inspect the oil filter for clogs or restrictions, and replace it if necessary. Check the oil pump for wear or damage, and test the oil pressure sensor for accuracy. If these components are functioning correctly, inspect the engine bearings and journals for excessive wear.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs