High-Quality Excavator Parts Suppliers: Reliable & User-Friendly

At our company, we are proud to be one of the leading excavator parts suppliers in the industry. With our extensive experience and expertise in product operations, we provide high-quality parts that are essential for the smooth functioning of excavators. Our product range includes a wide variety of parts such as hydraulic pumps, cylinders, tracks, engines, and much more. We understand the importance of reliable and durable parts for heavy-duty machinery like excavators, and that's why we only source our parts from trusted manufacturers.

We prioritize user-friendly content that is easy to understand and navigate. Our product descriptions are carefully crafted to convey the professionalism and reliability of our parts, making consumers feel trust and peace of mind when choosing our products for their excavators. Whether you are a professional construction contractor or operate a rental business, you can rely on our excavator parts to keep your machines running smoothly.

Furthermore, our attention to search engine optimization ensures that our website and product descriptions are easy to crawl and rank by . This means that when you search for excavator parts suppliers, you'll easily find our products and information to help you make the best purchasing decision. Our commitment to providing comprehensive and accurate product descriptions sets us apart as a trusted supplier in the industry.

Our Advantages

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

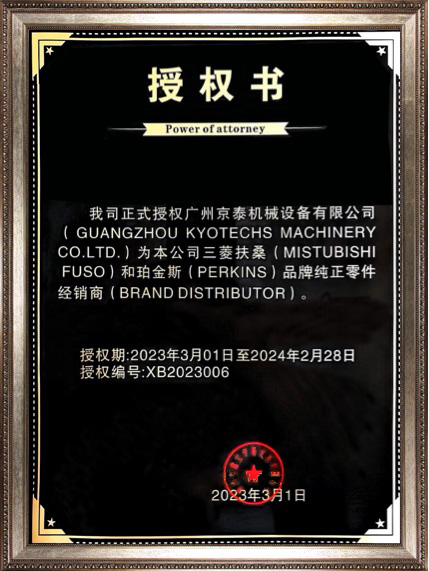

Certificate display

HANDOK Hydraulic

WYS

Perkins

Q&A

How often should the coolant be changed?

Usually the coolant is changed every two years or as recommended by the manufacturer.

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

How do you know if the perpendicularity between the ground gear plane and the bearing hole has changed?

It can only be found when assembling the gear pump, because the end face clearance is very small, generally around 0.05mm. If the perpendicularity between the end face and the bearing hole has changed, the gear shaft cannot move after the pump is assembled. If the locking screw is loosened a little, but it still does not turn smoothly, and the gear pump is disassembled and inspected, there are scratches on the end face. This is caused by the end face plane not being perpendicular to the bearing hole.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs