Kyotechs 0429-7075: Elevate Efficiency with Innovative Reliability

Introducing the Kyotechs 0429-7075, a game-changing addition to your toolkit, designed to enhance your operational efficiency and deliver unmatched performance. A masterpiece of engineering, this product stands out in terms of reliability and innovation, providing you with the edge you need in today's competitive environment.

Crafted with precision, the Kyotechs 0429-7075 boasts cutting-edge technology and superior materials, embodying the brand's commitment to quality and durability. The thoughtful design ensures seamless integration into your existing systems, making it not only a versatile choice but also a smart investment for long-term benefits.

What sets the Kyotechs 0429-7075 apart is its user-friendly interface coupled with robust functionality. This product delivers optimal performance with minimal maintenance, ensuring that you can focus on what truly matters—achieving your goals efficiently. Whether you're a seasoned professional or an enthusiastic beginner, the intuitive operation of the Kyotechs 0429-7075 guarantees ease of use without compromising on precision.

Additionally, the product’s eco-friendly design is a testament to Kyotechs' dedication to sustainability, ensuring minimal environmental impact without sacrificing performance. Stand out in your field with the Kyotechs 0429-7075, where reliability meets excellence.

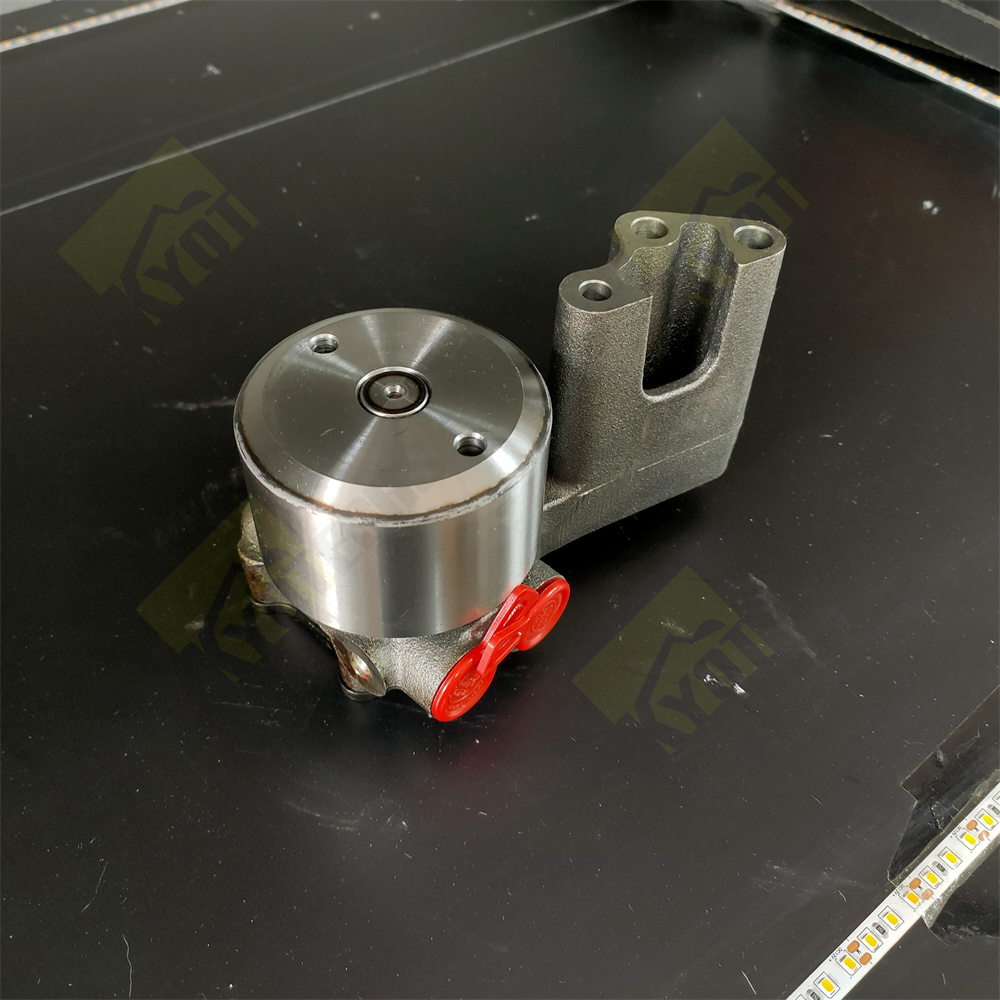

Product Image

Our Advantages

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

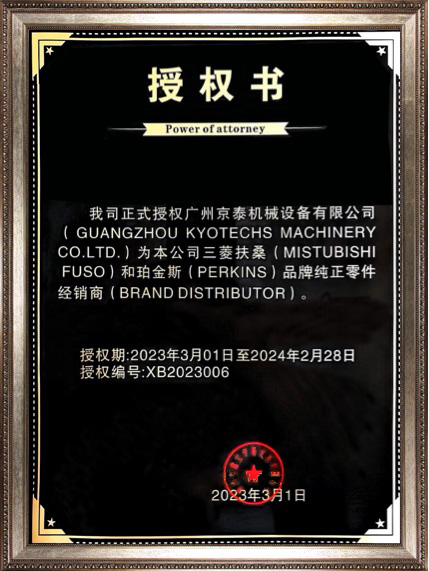

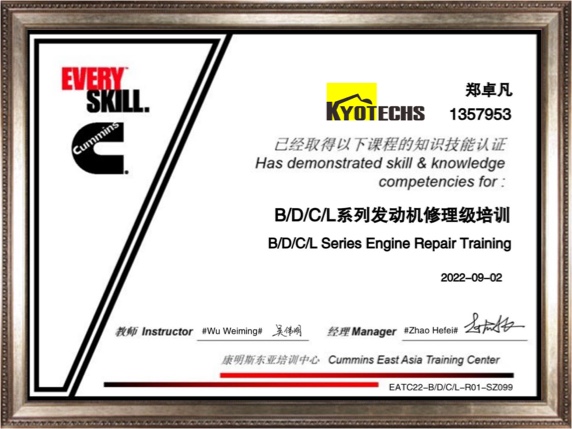

Qualification Certificate

WYS

Perkins

Cummins REPAIR TRAINING

FAQ

How to adjust the tension of the tracks?

To adjust the track tension, refer to the specific operation manual for the excavator model. Generally, this is done by adjusting the bolts on the tension cylinder or increasing/decreasing the pressure of the tension spring.

What are the reasons for the excavator crawler chain off?

1. Chain off caused by tension cylinder failure

At this time, you should check whether you have forgotten to butter the tension cylinder and see if there is any oil leakage in the tension cylinder.

2. Chain off caused by severe wear of the crawler

If used for a long time, the crawler will definitely be worn, and the wear of the chain ribs, chain barrels and other parts on the crawler will also cause the crawler chain off.

3. Chain off caused by wear of the chain guard

Now almost all excavator crawlers have chain guards, and chain guards can play a very important role in preventing chain off, so it is also very important to check whether the chain guard is worn.

4. Chain off caused by wear of the drive motor ring gear

For the drive motor ring gear, if it is severely worn, we need to replace it, which is also an important reason for the excavator chain off.

5. Chain off caused by damage to the sprocket wheel

Generally speaking, oil leakage of the sprocket wheel oil seal of the excavator will cause severe wear of the sprocket wheel, which will cause the crawler chain off. The public account Zhizao Daguan focuses on sharing relevant theoretical knowledge in the engineering machinery manufacturing industry.

6. Chain derailment caused by guide wheel damage

When checking the track guide wheel, check whether the screws on the guide wheel are missing or broken. Check whether the groove of the guide wheel is deformed.

What are the common faults of crawler excavator hydraulic pumps?

Common faults of hydraulic pumps include insufficient pressure, hydraulic oil leakage, abnormal noise, system overheating and wear of internal pump components.

How to repair damaged hydraulic pump impellers?

Possible cavitation or debris in the oil.

Solution: Replace damaged impellers, prevent cavitation, filter oil.

If you have another questions, please feel free to contact us.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs