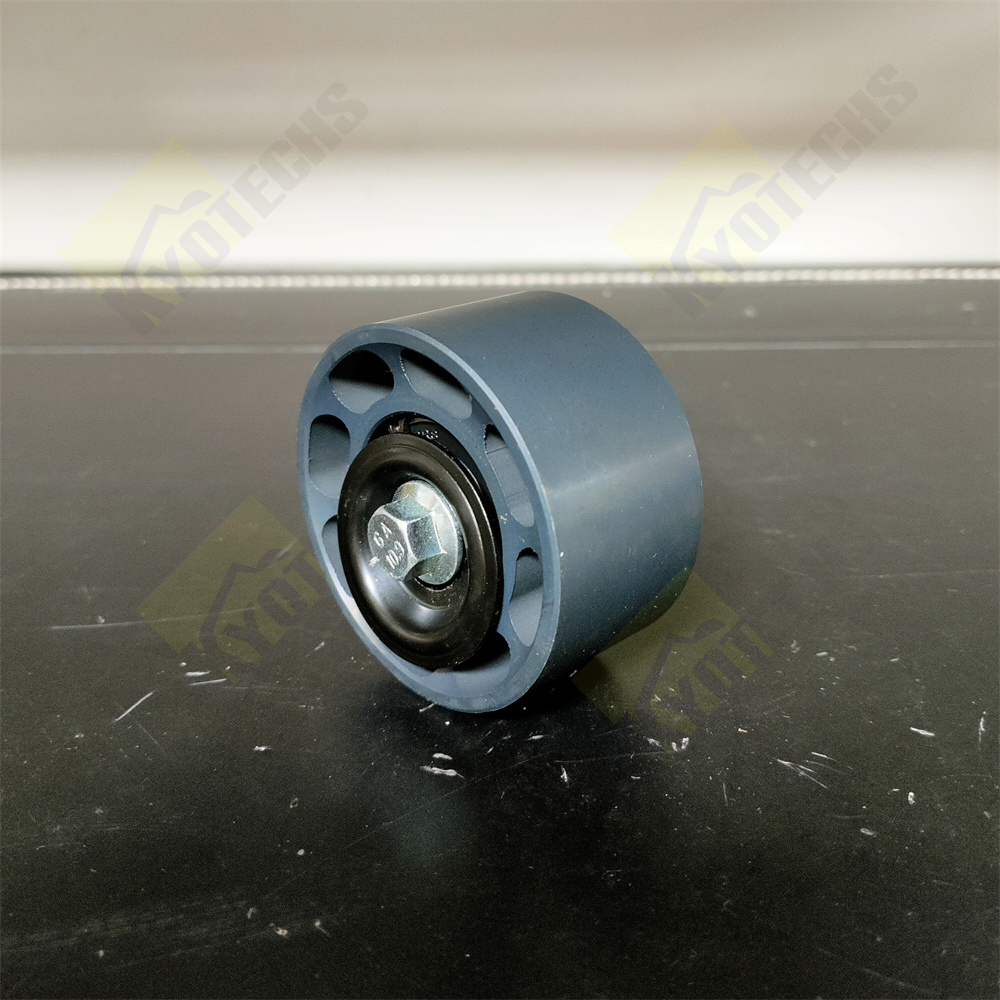

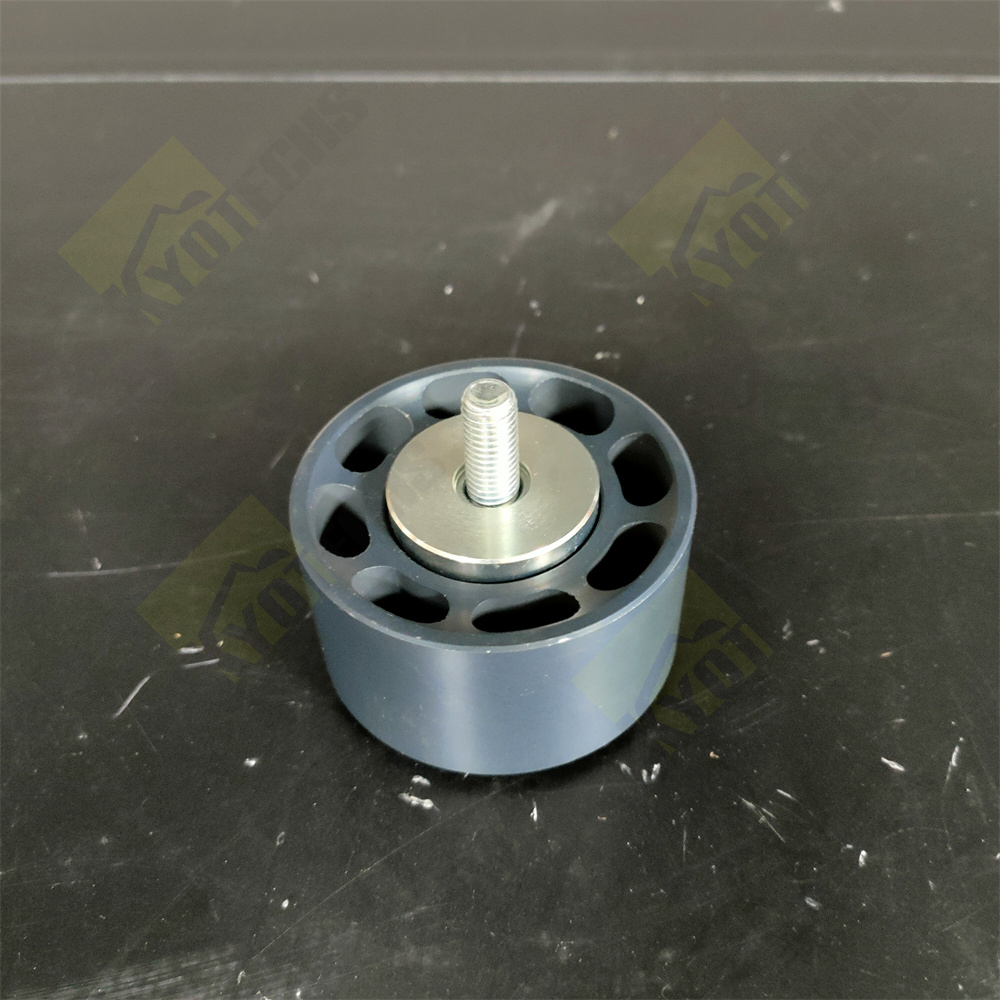

* Kyotechs 133-7023 Pulley Assy Idler - Durable & Efficient *

Discover the premium Kyotechs 133-7023 Pulley Assy Idler, specifically engineered for the Caterpillar C15 Engine. Our high-quality excavator spare parts ensure durability and optimal performance. Trust Kyotechs for reliable 133-7023 solutions. Enhance your machinery’s efficiency with our expertly crafted idler pulley.

Kyotechs 133-7023 Pulley Assy Idler: Your High-Performance Solution

Introducing the Kyotechs 133-7023 Pulley Assy Idler, a High-Quality component engineered to optimize the performance and reliability of your machinery. Crafted with precision and expertise, this pulley assembly is a testament to Kyotechs' commitment to quality and innovation. Whether you're in the construction, agricultural, or industrial sector, our pulley assy idler is designed to meet your demanding operational needs, providing seamless functionality and durability.

Kyotechs understands the importance of dependable equipment in ensuring the smooth running of operations. That's why the 133-7023 Pulley Assy Idler is manufactured to the highest standards, using cutting-edge technology and materials that ensure long-lasting performance. Its robust construction reduces wear and tear, minimizing downtime and maintenance costs – a crucial aspect in today's fast-paced environment.

This pulley assembly is easy to install and designed to fit perfectly with your machines, providing a hassle-free upgrade or replacement. Compatible with various models, it ensures versatility and broad applicability. Plus, our stringent quality assurance tests guarantee that each unit delivers consistent performance, giving you peace of mind and uninterrupted service.

By choosing Kyotechs, you are not just buying a product; you are investing in a solution that promises reliability, efficiency, and the support of a brand that stands behind every product they offer. Experience the difference with Kyotechs 133-7023 Pulley Assy Idler – where engineering excellence meets practical application.

*Summary:*

Durable and efficient pulley assy idler by Kyotechs ensures superior performance.

*Meta Title:*

Kyotechs 133-7023 Pulley Assy Idler - Durable & Efficient

*Meta Description:*

Optimize machine performance with Kyotechs 133-7023 Pulley Assy Idler. Reliable, durable, and easy to install.

Product Images

Advantages

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

Certificate display

HANDOK Hydraulic

Tongmyung

ISUZU

FAQ

Digging powerlessness is one of the typical faults of excavators

Digging powerlessness can be divided into two situations: one is digging powerlessness, the engine does not hold back, and the load feels very light; the second is digging powerlessness, when the boom or dipper stick is extended to the bottom, the engine is seriously held back or even stalled.

①, digging powerlessness but the engine does not hold back. The magnitude of the digging force is determined by the output pressure of the main pump, and whether the engine holds back depends on the relationship between the oil pump absorption torque and the engine output torque. The engine does not hold back, indicating that the oil pump absorption torque is small and the engine load is light. If the working speed of the excavator is not obviously abnormal, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked in particular. If the overflow pressure measurement value is lower than the specified value, it indicates that the overload overflow valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and powerlessness. The machine can be adjusted by turning the adjustment screw.

②, digging powerlessness, engine holding back. The engine holding back indicates that the absorption torque of the oil pump is greater than the engine output torque, causing the engine to overload. This fault should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system will resume normal function, the engine stalling phenomenon will disappear, and the digging force will return to normal.

How to remove air from the hydraulic system?

The way to remove air is to slowly operate all functions of the hydraulic system until the air is exhausted, and check and maintain the hydraulic oil level during this process.

How to check and adjust the track tension?

Check the tightness of the track through the tensioner and adjust it if necessary to ensure the normal operation of the track.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs