Kyotechs 274-6720 High Pressure Sensor - Reliable & Accurate

Product Description

Introducing the Kyotechs 274-6720 High Pressure Sensor—a reliable solution for precision and performance. Designed to meet the needs of demanding applications, this high pressure sensor ensures accurate readings and long-lasting durability, making it indispensable for professionals who prioritize reliability and safety in their equipment.

Crafted with advanced technology, the Kyotechs 274-6720 stands out in the market with its robust construction and superior efficiency. It offers seamless integration into your system, delivering accurate pressure measurements that help optimize your operational efficiency and reduce downtime.

Kyotechs is a trusted brand known for its commitment to quality and innovation. Each 274-6720 High Pressure Sensor undergoes rigorous testing to ensure it meets our high standards, providing you with peace of mind and confidence in its ability to withstand high-pressure environments.

Whether you’re operating heavy machinery or sophisticated industrial systems, this sensor is an essential component that guarantees your operations run smoothly. Its easy installation process and low maintenance requirements further enhance its appeal, saving you valuable time and resources.

By choosing the Kyotechs 274-6720 High Pressure Sensor, you’re investing in a product that combines professionalism with reliability. Trust in Kyotechs to deliver a sensor that not only meets but exceeds your expectations, offering unmatched value for your high-pressure sensor needs.

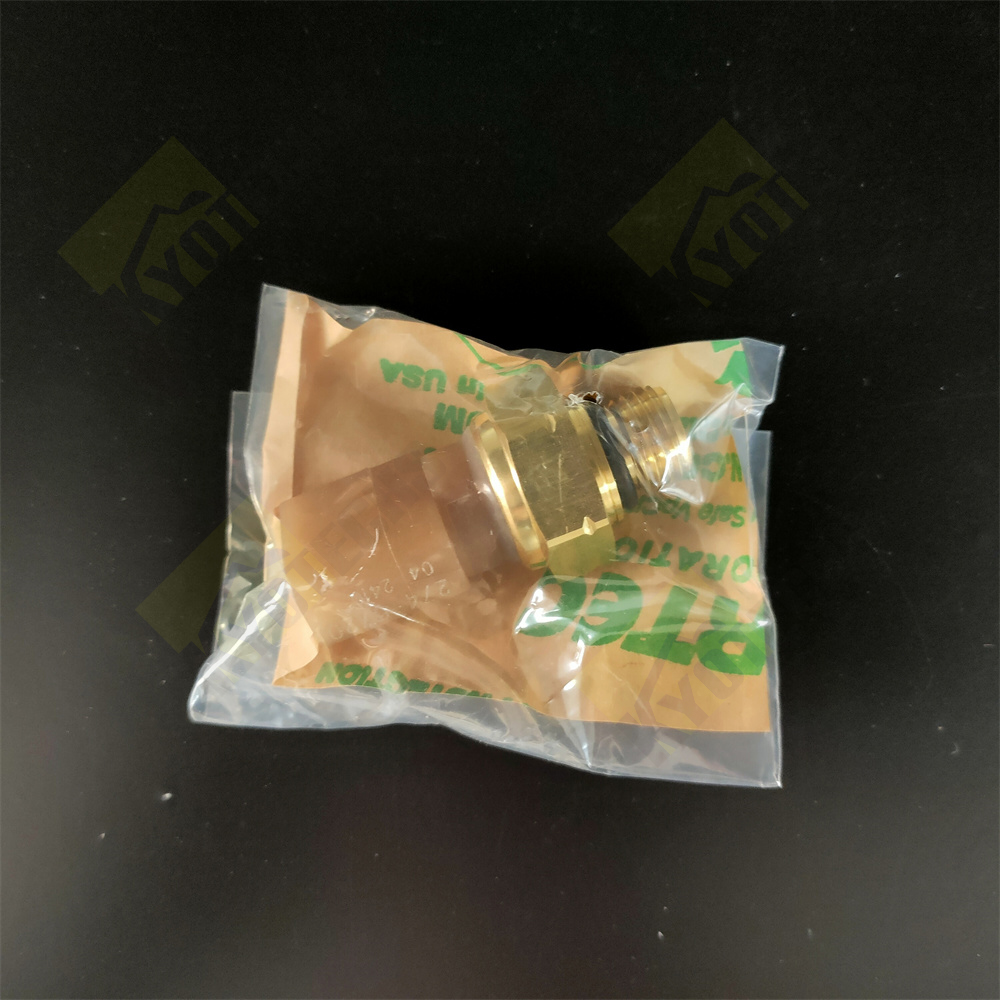

Picture Show

Our Advantages

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Our Certifications

Cummins

HANDOK Hydraulic

Tongmyung

FAQ

Digging powerlessness is one of the typical faults of excavators

Digging powerlessness can be divided into two situations: one is digging powerlessness, the engine does not hold back, and the load feels very light; the second is digging powerlessness, when the boom or dipper stick is extended to the bottom, the engine is seriously held back or even stalled.

①, digging powerlessness but the engine does not hold back. The magnitude of the digging force is determined by the output pressure of the main pump, and whether the engine holds back depends on the relationship between the oil pump absorption torque and the engine output torque. The engine does not hold back, indicating that the oil pump absorption torque is small and the engine load is light. If the working speed of the excavator is not obviously abnormal, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked in particular. If the overflow pressure measurement value is lower than the specified value, it indicates that the overload overflow valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and powerlessness. The machine can be adjusted by turning the adjustment screw.

②, digging powerlessness, engine holding back. The engine holding back indicates that the absorption torque of the oil pump is greater than the engine output torque, causing the engine to overload. This fault should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system will resume normal function, the engine stalling phenomenon will disappear, and the digging force will return to normal.

Why does the hydraulic pump make a high-pitched noise?

Possible air in the hydraulic oil or internal component wear.

Solution: Bleed air from the system, replace worn components.

What are the common causes of failure of hydraulic pump control valves?

Common causes of control valve failure include internal wear, seal damage, contamination and valve blockage.

How to check the hydraulic oil level?

Park the excavator on a flat ground, turn off the engine and wait for a while, then check the hydraulic oil level through the oil level gauge of the hydraulic oil tank.

If you have any questions about our goods or services, please feel free to contact us.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs