Kyotechs 274-6720: Professional-Grade Reliability

Product Description

Experience unparalleled quality and reliability with the Kyotechs 274-6720, a High-Quality product designed to meet your professional needs. Kyotechs has established itself as an industry leader known for blending cutting-edge technology with proven reliability. The 274-6720 is a testament to this legacy, engineered to deliver exceptional performance and unwavering durability in all operational conditions.

Crafted with precision and attention to detail, the Kyotechs 274-6720 suits various applications, providing users with both versatility and peace of mind. Manufactured using high-quality materials, this product ensures longevity and consistent operation, minimizing downtime and guaranteeing efficient workflow management for your business.

The 274-6720 is rigorously tested to meet the most stringent industry standards, embodying Kyotechs' commitment to excellence. Whether you are updating your existing systems or embarking on a new project, Kyotechs 274-6720 offers seamless integration and compatibility, making it a trusted choice for professionals worldwide.

Choose Kyotechs 274-6720 for your operational needs and benefit from a product that prioritizes your success with its performance-driven design. It’s not just a product; it’s a reliable partner in your professional endeavors.

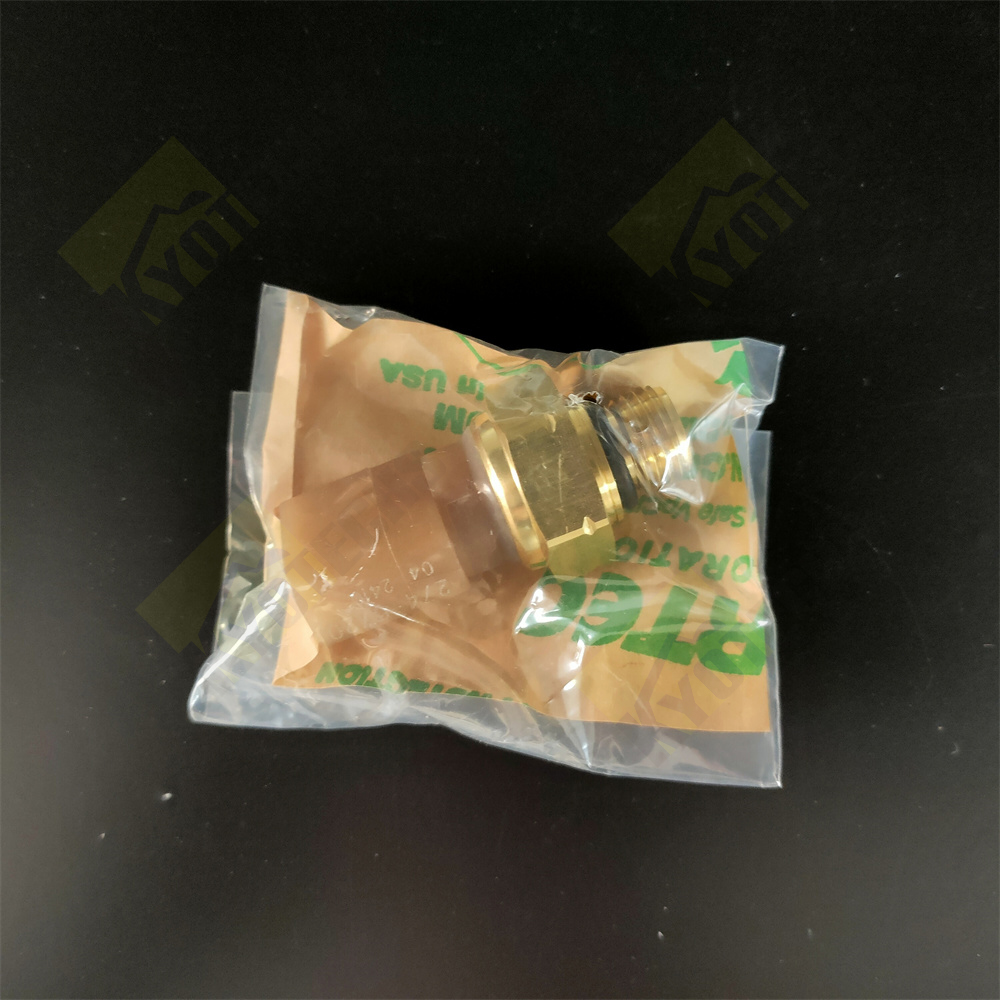

Detailed display

Advantages

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Certifications

Cummins

Cummins BETT & INSITE

WYS

FAQ

How do you know if the perpendicularity between the ground gear plane and the bearing hole has changed?

It can only be found when assembling the gear pump, because the end face clearance is very small, generally around 0.05mm. If the perpendicularity between the end face and the bearing hole has changed, the gear shaft cannot move after the pump is assembled. If the locking screw is loosened a little, but it still does not turn smoothly, and the gear pump is disassembled and inspected, there are scratches on the end face. This is caused by the end face plane not being perpendicular to the bearing hole.

What kind of battery is used in the excavator? Why?

The batteries we use are all lead-acid batteries for starting. Because this type of battery has the characteristics of large starting current and can meet the power supply requirements of the starter motor.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

What to do if the excavator has an oil leak?

To address oil leaks, inspect seals, fittings, and lines. Locate the leak, tighten any loose fittings, and replace worn or damaged seals and lines. Clean the area and recheck for leaks.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs