Kyotechs 29335 Engine: Power, Efficiency, and Reliability

Introducing the Kyotechs Excavator Parts Engine Assembly 29335 Engine S4Q2, expertly crafted for optimal performance in HR18 excavators. Our high-quality 29335 Engine ensures durability, efficiency, and reliability for demanding construction projects. With Kyotechs, experience seamless integration and superior functionality tailored to meet industry standards. Upgrade your machinery with this meticulously engineered part, boosting productivity and longevity. Trust Kyotechs for your excavator needs – choose the 29335 Engine Assembly for unparalleled performance and peace of mind.

Kyotechs 29335 Engine: Precision Performance Meets Unmatched Reliability

Introducing the Kyotechs 29335 Engine, a meticulously crafted powerhouse designed for those who demand excellence in performance and high quality reliability. Whether you're looking to enhance the efficiency of industrial machinery or elevate the capabilities of your personal project, the Kyotechs 29335 Engine stands as a testament to innovative engineering and robust functionality.

Unparalleled Efficiency and Power

At the heart of the Kyotechs 29335 Engine lies its advanced technology that ensures maximum output with minimal fuel consumption. This engine not only optimizes power generation but also reduces operational costs, making it an ideal choice for budget-conscious users without compromising on power delivery. With this engine, you experience the perfect balance of efficiency and power that keeps your operations running smoothly and effectively.

Engineered for Longevity

Crafted with precision and durability in mind, the Kyotechs 29335 Engine is built to withstand the rigors of the most demanding environments. Its components are made from high-strength materials that promise an extended lifespan, ensuring that your investment remains secure for years to come. This engine's ability to perform under high stress without faltering is what sets it apart from the competition, making it a reliable partner in your operations.

Versatile Applications

The versatility of the Kyotechs 29335 Engine makes it suitable for a vast range of applications. From industrial settings to heavy-duty construction equipment, this engine adapts seamlessly to any challenge you throw its way. Its adaptability ensures that you can tackle various projects without needing multiple engines, thereby simplifying your machinery lineup and reducing overhead costs.

Silent Yet Powerful Operation

Experience the perfect blend of power and quietness with the Kyotechs 29335 Engine. Thanks to innovative noise-reduction technology, this engine runs smoothly and quietly, minimizing noise pollution in work environments. This feature not only promotes a better working atmosphere but also aligns with eco-friendly practices by reducing sound emissions.

Unmatched Support and Service

Choosing the Kyotechs 29335 Engine also means gaining access to Kyotechs' renowned customer service and support. Our expert team is committed to assisting you with any inquiries, ensuring your engine operates at peak performance throughout its lifespan. With comprehensive service options and readily available spare parts, maintaining your engine has never been more straightforward.

Embrace the future of engineering excellence with the Kyotechs 29335 Engine. Its combination of power, efficiency, durability, and versatility make it the go-to choice for savvy professionals and enthusiasts alike. Explore the potential of your machinery with Kyotechs and redefine what's possible today.

Picture Show

Advantages

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

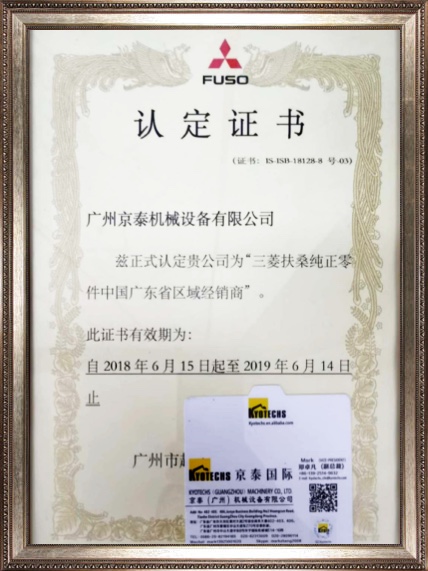

Certifications

SANY Power

MITSUBISHI FUSO

Tongmyung

Question you may concern

What to do if the hydraulic pump makes abnormal noises?

Abnormal noises from the hydraulic pump may be due to air entering the hydraulic system, contaminated hydraulic oil, or internal wear of the hydraulic pump. Check the condition of the hydraulic oil, inspect the suction line for leaks, and replace the hydraulic pump or related components if necessary.

What to do if the excavator has an oil leak?

To address oil leaks, inspect seals, fittings, and lines. Locate the leak, tighten any loose fittings, and replace worn or damaged seals and lines. Clean the area and recheck for leaks.

What to do if the excavator has difficulty starting?

Check the battery charge and connections, inspect the starter motor and ignition system, ensure the fuel system is supplying fuel properly, and read fault codes for further diagnostics.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

Excavator Spare Parts 21N8-20505 Switch Membrane For Hyundai R210LC-7

Excavator Parts 31N6-25130 Solenoid Valve For Hyundai R160LC-7

Excavator Spare Parts YB60000571 Pilot Valve For Hitachi ZX60

Excavator Spare Parts 8-98197654-0 Front Shock Absorber For ISUZU

Excavator Spare Parts 14714208 Control Valve For Volvo EC220E

Excavator Parts 5659737 Hydraulic Pump For Caterpillar 336GC

Bulldozer Hydraulic Main Control Valve 723-63-24100 For Komatsu D65-15

D31 Bulldozer Hydraulic Pump Ass'y 720-2M-00031 For Komatsu D31EX-21

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs