Kyotechs 4686827 - Superior Performance and Reliability

Introducing the Kyotechs 4686827, where innovation meets practicality. This exceptional product is designed with your needs in mind, offering a seamless blend of functionality and reliability. Trusted by professionals, Kyotechs stands at the forefront of industry standards, ensuring that every product is crafted to deliver superior performance.

The 4686827 model exemplifies Kyotechs' commitment to quality. It's engineered for durability and efficiency, making it an indispensable tool for various applications. Whether you're tackling a complex project or handling everyday tasks, the 4686827 provides unmatched precision and strength. Its robust construction ensures longevity, minimizing the need for frequent replacements and providing you with peace of mind.

What sets the Kyotechs 4686827 apart is its user-friendly design. Intuitively crafted for ease of use, even first-time users will find it straightforward to operate. Its sleek design is not only aesthetically pleasing but also ergonomically optimized to enhance comfort during prolonged use.

Backed by Kyotechs' exceptional customer service, purchasers of the 4686827 can feel confident in their investment. Every unit comes with comprehensive support, ensuring that you have the assistance you need, whenever you need it.

This product is more than just a tool; it's a testament to Kyotechs' dedication to enhancing user experience and delivering tangible value. Choose the 4686827 and experience the assurance of a product designed with you in mind.

Detailed display

Advantages

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

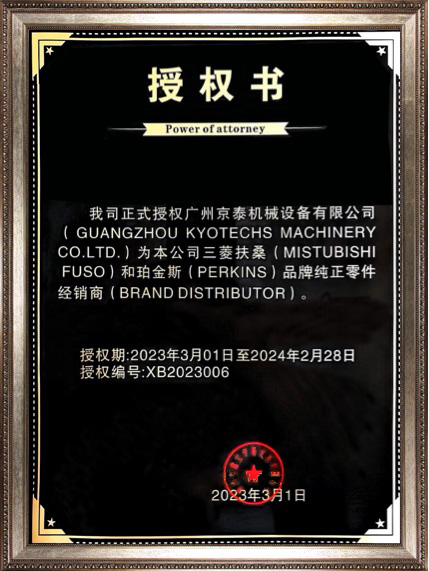

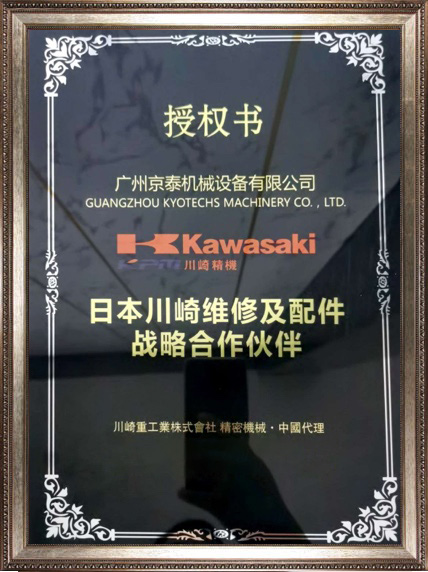

Qualification Certificate

Tongmyung

Perkins

KAWASAKI

Q&A

What is the role of the battery on the construction machinery we use, such as loaders, excavators, forklifts, etc.?

The role of the battery (battery) is to supply the short-term huge discharge current (300-500A) required for the starter motor. When the generator does not generate electricity, or the generator generates insufficient electricity at low speed and the generator is overloaded, it can supply power to the electrical equipment. It can also convert the electrical energy provided by the generator into chemical energy and store it, and then supply power to the electrical equipment.

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

What is the maintenance frequency of the hydraulic pump?

The maintenance frequency of the hydraulic pump is usually performed every 1000 to 2000 hours of operation or once a year according to the manufacturer's recommendations.

What are the conditions for good starting performance of excavators?

- There must be enough starting speed. The high starting speed means less gas leakage in the cylinder, shorter heat transfer time of compressed air to the cylinder wall, less heat loss, and higher gas temperature and pressure at the end of compression. Generally, the speed is required to be above 100r/min.

2. The cylinder should have good sealing. This can further reduce the amount of leakage and ensure that the gas has sufficient combustion temperature and pressure at the end of compression. The compression pressure of the cylinder shall not be lower than 8_0_%_ of the standard value.

3. The engine is required to have appropriate clearance relative to the running parts and good lubrication.

4. The battery must have sufficient starting capacity and the technical condition of the starting circuit is normal.

5. The starting oil volume meets the requirements, the injection quality is good, and the injection advance angle meets the requirements.

6. Use fuel that meets the requirements

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs