Kyotechs 505-0527 Hydraulic Main Pump: Efficiency & Reliability

Introducing the Kyotechs 505-0527 Hydraulic Main Pump – a powerhouse in hydraulic engineering designed to elevate the performance of your machinery. Whether you're operating heavy-duty construction equipment or agricultural machinery, the Kyotechs Hydraulic Main Pump ensures your operations run smoothly and efficiently.

Engineered with precision and crafted from high-quality materials, this hydraulic pump promises reliability and durability. The 505-0527 model is renowned for its exceptional performance under pressure, delivering consistent fluid power to support a wide range of hydraulic applications. Its robust design minimizes downtime and maximizes productivity, making it an invaluable asset to your equipment.

Beyond performance, the Kyotechs 505-0527 Hydraulic Main Pump is all about user satisfaction. Our commitment to excellence extends to providing users with an easy installation process, saving you valuable time and resources. Plus, with customer service that puts you first, we're here to support you every step of the way, ensuring you feel valued and cared for.

Environmentally conscious? The 505-0527 pump is designed to operate efficiently, reducing fuel consumption while maintaining peak power. This translates to cost savings and a smaller carbon footprint, aligning your operations with sustainability goals.

Choose the Kyotechs 505-0527 Hydraulic Main Pump – because efficient, reliable performance shouldn’t be a luxury; it’s a standard we set for every user.

Product Images

Our Advantages

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

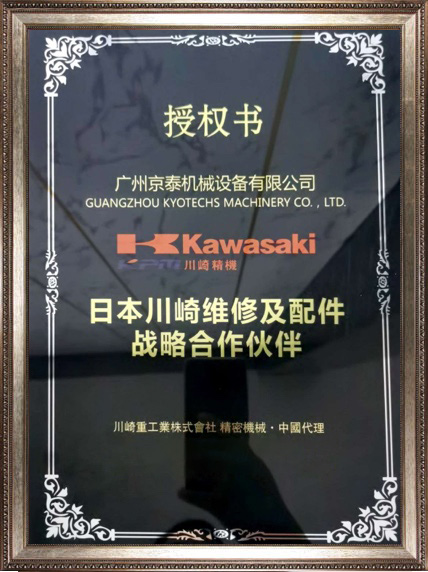

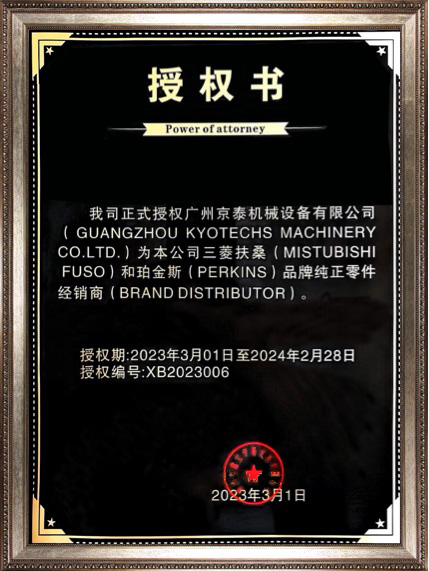

Our Certifications

KAWASAKI

Perkins

Cummins

Question you may concern

How to check for leaks in the hydraulic system?

Check whether there are oil stains on the hydraulic oil tank, oil pipe and joints, and repair them in time if leaks are found.

How do you diagnose a faulty fuel injector in an excavator engine?

To diagnose a faulty fuel injector, listen for any unusual engine noises or misfires. Perform a balance test to identify which injector is causing the problem. Use a diagnostic tool to check for fault codes related to the fuel system. If necessary, remove and inspect the injector for signs of clogging or damage, and replace it if needed.

What is the maintenance frequency of the hydraulic pump?

The maintenance frequency of the hydraulic pump is usually performed every 1000 to 2000 hours of operation or once a year according to the manufacturer's recommendations.

What is the reason for the cylinder pulling in the excavator engine?

Reasons from the piston group

1. The piston ring gap is too small. If the opening gap, side gap or back gap of the piston ring is too small, the piston ring will be stuck due to heat expansion when the engine is working, and it will be pressed tightly against the cylinder wall, or the piston ring will be broken, which can easily pull out grooves on the cylinder wall.

2. The piston pin is out. Because the piston pin retaining ring is not installed or falls off or breaks, the piston pin will be out during movement, which can easily damage the inner wall of the cylinder and cause the cylinder to blow into the crankcase.

3. The piston cylinder gap is too small or too large. If the piston material is poor, the manufacturing size error is too large, or the piston is deformed after the piston pin is assembled, the matching gap between the piston and the cylinder is too small, and the piston is stuck after heat expansion, which will then damage the cylinder wall.

4. The piston ring is seriously carbonized. Excessive carbon deposits cause the piston ring to stick or bite in the ring groove. At the same time, carbon deposits are a hard abrasive that will grind into longitudinal grooves on the cylinder wall.

5. The piston is seriously off-cylinder. Due to the bending and twisting of the connecting rod, the parallelism and coaxiality deviations of the connecting rod journal, main journal, and piston pin seat are too large, causing the piston to be significantly off-cylinder, which will accelerate the wear of the piston ring, piston and cylinder wall and destroy the formation of the oil film.

Reasons for cylinder sleeves

1. The roundness and cylindricality tolerances of the cylinder sleeves exceed the allowable range, which greatly reduces the sealing of the piston and cylinder sleeves. The high-temperature gas in the cylinder flows down, destroying the oil film between the piston and the cylinder wall, and then causing cylinder pulling.

2. The cylinder sleeve is deformed during the assembly process. For example: the protrusion of the upper end surface of the cylinder sleeve is too large, and the cylinder sleeve is deformed after the cylinder head is installed; the cylinder sleeve water blocking ring is too thick, and the cylinder sleeve is deformed after being pressed into the body, which can easily cause cylinder pulling.

Reasons for use:

1. Whether the size of the cylinder sleeve used during assembly does not match the cylinder body and piston.

2. The air filter is not sealed, which makes the filtering effect worse. Dust, sand and other impurities in the air are sucked into the cylinder, forming abrasive wear. Tests show that if a few grams of dust are sucked in every day, the wear of the cylinder liner will increase by more than 10 times.

If you have another questions, please feel free to contact us.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs