Kyotechs 595-9505: Efficiency & Reliability Redefined

Unleash Efficiency with Kyotechs 595-9505

Introducing the Kyotechs 595-9505, a cutting-edge solution designed specifically for those who demand efficiency and reliability from their equipment. As a trusted name in the industry, Kyotechs has engineered this product to enhance productivity while maintaining the durability required for the most challenging environments.

Practicality Meets Performance

The Kyotechs 595-9505 is crafted with your practical needs in mind. This product boasts a robust design to withstand heavy-duty operations, making it ideal for construction and industrial applications. With precision engineering, it ensures seamless integration and optimal performance with your existing machinery, minimizing downtime and maximizing productivity. Its user-friendly interface allows for easy operation, making even the most complex tasks straightforward and manageable for operators at any skill level.

Value Beyond Expectations

At Kyotechs, we understand the importance of delivering value to our customers. The 595-9505 model is not just a piece of equipment; it’s a partnership that promises enhanced work efficiency. This product reduces operational costs by decreasing maintenance frequency and extending service life, giving you more time to focus on what truly matters—your work.

Customer-Centric Design

The Kyotechs 595-9505 reflects a commitment to listening to and understanding your needs. We have incorporated feedback from industry professionals to ensure our product meets your expectations. This model features intuitive controls and customizable settings, allowing you to tailor its functions to suit specific tasks. Additionally, it comes with comprehensive support and a warranty that underscores our confidence in the product’s longevity and performance.

Built for Sustainability

Modern challenges require solutions that are not only efficient but also environmentally responsible. The Kyotechs 595-9505 supports sustainable practices by incorporating energy-saving features that reduce the overall environmental footprint without compromising on power or efficiency. Investing in this product means choosing a path toward more sustainable operations, fulfilling your commitments to both business excellence and environmental stewardship.

Elevate Your Operations Today

Choose the Kyotechs 595-9505 to transform your operations with a product that prioritizes your needs, provides exceptional value, and supports sustainable practices. Let Kyotechs be your trusted partner in success. Feel the care and dedication we’ve put into this product and experience an upgrade that genuinely makes a difference.

Product Images

Advantages

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

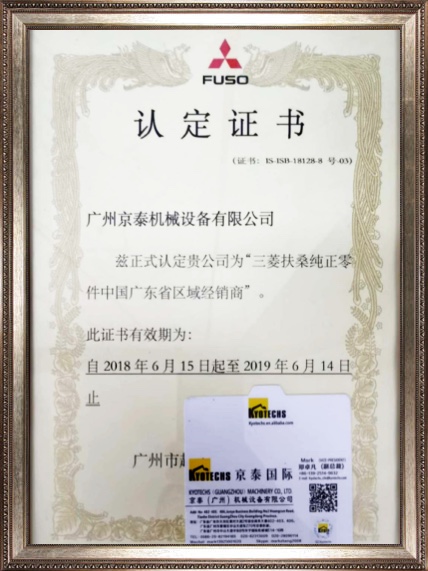

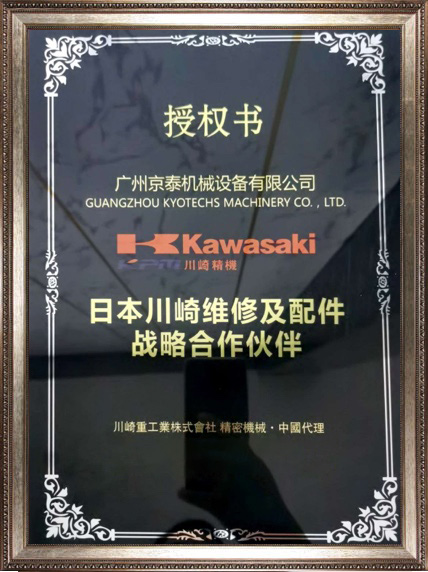

Certifications

MITSUBISHI FUSO

KAWASAKI

Tongmyung

Q&A

How to address electrical failures in hydraulic pumps?

Possible loose connections, damaged wiring, or sensor failure.

Solution: Tighten connections, repair wiring, replace faulty sensors.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

What causes hydraulic pump control valve failure?

Possible oil contamination, internal wear, or improper maintenance.

Solution: Replace hydraulic oil, replace worn components, perform regular maintenance.

How often should the hydraulic oil be changed?

Usually the hydraulic oil is changed every 2000 hours or as recommended by the manufacturer.

Excavator Spare Parts 21N8-20505 Switch Membrane For Hyundai R210LC-7

Excavator Parts 31N6-25130 Solenoid Valve For Hyundai R160LC-7

Excavator Spare Parts YB60000571 Pilot Valve For Hitachi ZX60

Excavator Spare Parts 8-98197654-0 Front Shock Absorber For ISUZU

Excavator Spare Parts 14714208 Control Valve For Volvo EC220E

Excavator Parts 5659737 Hydraulic Pump For Caterpillar 336GC

Bulldozer Hydraulic Main Control Valve 723-63-24100 For Komatsu D65-15

D31 Bulldozer Hydraulic Pump Ass'y 720-2M-00031 For Komatsu D31EX-21

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs