Kyotechs 723-47-27501: Reliable and Efficient Machinery Component

Discover the Kyotechs 723-47-27503 Control Valve, designed specifically for Komatsu models PC400-7, PC400-8, PC450-8, and PC300-7. Enhance your excavator’s performance with our reliable, durable spare parts. Perfectly replacing 723-47-27501, it ensures optimal functionality and efficiency. Elevate your operations with Kyotechs quality today.

Product Description

Discover the Unmatched Reliability of the Kyotechs 723-47-27501

In the world of heavy machinery, there's little room for error. Precision, durability, and reliability are not mere options—they're necessities. Enter the Kyotechs 723-47-27501, a beautifully engineered component designed with the utmost attention to detail and quality. This part is an integral cog in the grand machinery that keeps your operations running smoothly, efficiently, and, most importantly, sustainably.

Kyotechs, a brand synonymous with excellence, has long stood at the forefront of the heavy machinery industry. With a storied legacy of delivering high-performance components, Kyotechs understands the intricacies and demands of your operational needs. The 723-47-27501 is a testament to this commitment—offering industry-leading features that meet and exceed expectations.

Superior Material Quality

Crafted from high-grade materials, the Kyotechs 723-47-27501 component ensures longevity and durability, even under the most strenuous conditions. Its robust construction withstands wear and tear, reducing downtime and maintenance costs. With a laser focus on quality, Kyotechs ensures that every 723-47-27501 part rolling off the production line adheres to strict quality control standards.

Exceptional Compatibility

One of the standout features of the Kyotechs 723-47-27501 is its exceptional compatibility. This versatile component is designed to seamlessly integrate with a variety of machinery, providing a perfect fit that guarantees optimal performance. It eliminates the hassles of compatibility issues, allowing for straightforward installation and immediate utility, thus saving precious time and resources.

Unmatched Efficiency

Efficiency is key in any operational setup, and the 723-47-27501 part is engineered to improve your processes. Its advanced design contributes to the overall efficiency of the machinery by optimizing power transfer and reducing friction, which translates into energy savings and increased output. With this component as part of your equipment, you can ensure operations are running at peak performance, delivering more while consuming less.

Innovative Design

Every Kyotechs 723-47-27501 part is a product of innovation. The design team leverages cutting-edge technology and user feedback to refine and perfect every aspect of the component. This focus on innovation ensures the 723-47-27501 meets the current demands while staying adaptable for future advances in machinery technology.

Eco-friendly Efficiency

In today's eco-conscious world, the Kyotechs 723-47-27501 stands out for its commitment to sustainability. Manufactured with eco-friendly processes and materials, it minimizes environmental impact without compromising on performance or efficiency. Kyotechs believes that progress in machinery should complement our planet, and the 723-47-27501 is proof of that philosophy.

In conclusion, choosing the Kyotechs 723-47-27501 means choosing longevity, reliability, and efficiency. It's not just a part—it's a promise of quality and performance that meets the rigorous demands of your machinery while ensuring environmental responsibility. Equip your operations with the Kyotechs advantage and experience the peak of engineering excellence.

Detailed display

Our Advantages

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

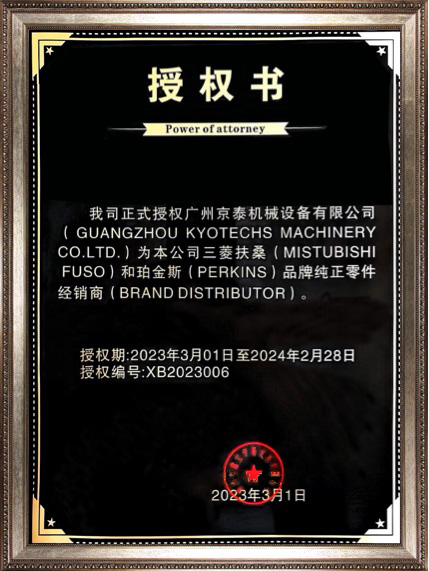

Qualification Certificate

WYS

ISUZU

Perkins

Frequently Asked Questions

How to remove air from the hydraulic system?

The way to remove air is to slowly operate all functions of the hydraulic system until the air is exhausted, and check and maintain the hydraulic oil level during this process.

What is the matter with the engine speed drop when the excavator is working? How to solve it?

8 reasons for the engine speed drop of the excavator, 6 solutions are here!

As the name suggests, engine speed drop means the failure of the engine speed drop during the operation of the excavator. There are two manifestations of speed drop, one is a slight speed drop within 200 revolutions, and the other is a serious speed drop above 300 revolutions, which is likely to cause the excavator to suddenly shut down. There are 8 main reasons for the engine speed drop of the excavator.

1. The diesel oil circuit of the excavator is faulty. Generally speaking, when the diesel oil circuit is blocked, it may cause the speed drop phenomenon.

2. The hydraulic system of the excavator has a fault, so that the hydraulic pump cannot change the displacement normally, causing the system pressure to be too high, and the speed drop may also cause a machine failure.

3. The output power of the excavator engine itself is insufficient, the output power is lower than the rated power, and the speed is too low. There is also a problem with the main pump.

4. The engine uses fuel of poor quality or the water content of the fuel is too high, which will lead to insufficient engine power and speed drop.

5. When the air intake system leaks or is blocked, the engine will be short of air supply, resulting in incomplete combustion of fuel, and there will be speed drop and black smoke failure.

6. Due to the large gap of the solenoid valve, the fuel supply is insufficient, which causes the engine to drop.

7. The joint of the fuel supply circuit of the fuel system is loose or the pipeline is broken, causing fuel leakage or foreign matter blockage, resulting in insufficient fuel supply. In addition to speed drop, it may also cause flameout.

8. There are many reasons for speed drop, such as incorrect valve clearance, wrong injection timing, damaged turbocharger, faulty brakes, etc.

Having said so many reasons for the speed drop of the excavator engine, what should we do when the speed drop occurs?

The solutions are all here!

1. First, check whether the diesel used in the excavator is deteriorated, whether there are impurities in the oil, and whether the oil circuit is blocked.

2. Check the valve clearance of the excavator engine and the speed of the engine.

3. Check the intake pipeline, clean the air pre-filter and air filter element, and start the engine again.

4. Check whether the speed drop of the excavator occurs when the engine is under load?

5. Carefully check the engine to see if the engine failure causes the speed drop of the excavator engine.

6. In addition, the electronic control, hydraulic system, fuel system, etc. need to be checked.

Why do you need to check and replace the engine belt regularly?

Regularly checking and replacing the engine belt can prevent the belt from breaking and ensure the normal operation of the engine.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs