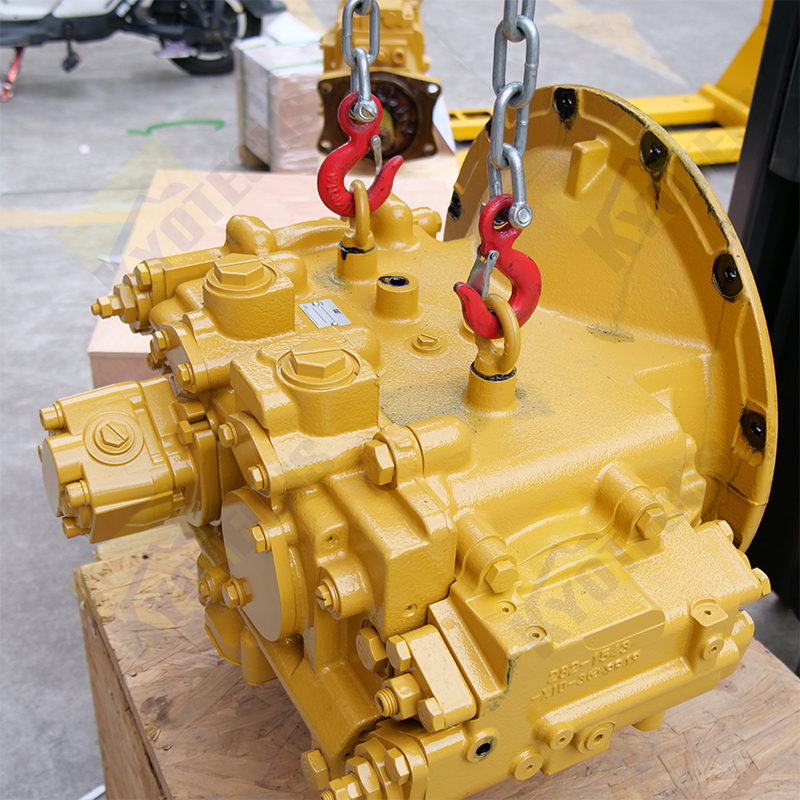

Kyotechs E319D Hydraulic Main Pump - Power and Reliability

Introducing the Kyotechs E319D Hydraulic Main Pump – a symbol of excellence and reliability in heavy machinery components. Engineered for optimal performance, this cutting-edge hydraulic main pump is designed explicitly for construction and industrial applications where efficiency and durability are paramount. Recognized for its superior craftsmanship, the Kyotechs E319D is the perfect solution for heavy-duty equipment operators looking for a dependable and powerful hydraulic pump that ensures precision and control.

The Kyotechs E319D Hydraulic Main Pump is crafted with the latest technology and materials, promising a product that is both robust and reliable. This advanced pump integrates seamlessly into your machinery, providing smoother and more efficient operations that enhance overall productivity. With its impressive hydraulic power, it helps in reducing operation time while simultaneously lowering maintenance costs, making this hydraulic main pump a smart investment for any construction or industrial business.

Quality and precision are at the heart of Kyotechs' manufacturing process. The E319D Hydraulic Main Pump is built to withstand the harshest working conditions, delivering consistent performance when you need it the most. Its design ensures a perfect fit and function within your machinery system, minimizing downtime and optimizing performance. Kyotechs prioritizes customer needs, engineering products that deliver not just on performance, but on longevity and reliability too.

Committed to providing a seamless experience, Kyotechs offers comprehensive after-sales support and service. Whether you are installing a new unit or require assistance with your existing setup, Kyotechs' dedicated support team is readily available to guide you through every step, ensuring your operations remain uninterrupted. Our customer-centric approach means you can trust Kyotechs to have your back, allowing you to focus on what you do best.

Beyond performance and support, the Kyotechs E319D Hydraulic Main Pump is also designed with sustainability in mind. Energy-efficient and eco-friendly materials contribute to a reduced environmental footprint, reflecting Kyotechs' commitment to responsible manufacturing practices. This balance of power, efficiency, and sustainability makes the E319D not just a tool for today’s challenges but a promise for tomorrow’s opportunities.

In summary, the Kyotechs E319D Hydraulic Main Pump offers unmatched functionality, reliability, and service support while prioritizing both your operational needs and environmental responsibility. By choosing Kyotechs, you are investing in not just a product, but in a partnership aimed at helping your business thrive. Experience the Kyotechs difference with the E319D Hydraulic Main Pump – where precision meets power.

Product Images

Advantages

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

One-Stop Excavator Software Solution

Kyotechs offer a comprehensive "One-Stop Excavator Software Solution" designed to solve engine ECU, excavator controller, and monitor software issues.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Our Certifications

Perkins

Cummins BETT & INSITE

ISUZU

Q&A

How to vent the hydraulic pump after installation?

The way to vent after installation is to slowly operate all functions of the hydraulic system until the air is exhausted, and check and maintain the hydraulic oil level during this process.

How to bleed air from the excavator's hydraulic system?

Start the excavator and let the hydraulic system run for a while. Operate all hydraulic functions to expel air, check the hydraulic tank oil level, and add hydraulic oil to ensure the system is full.

Digging powerlessness is one of the typical faults of excavators

Digging powerlessness can be divided into two situations: one is digging powerlessness, the engine does not hold back, and the load feels very light; the second is digging powerlessness, when the boom or dipper stick is extended to the bottom, the engine is seriously held back or even stalled.

①, digging powerlessness but the engine does not hold back. The magnitude of the digging force is determined by the output pressure of the main pump, and whether the engine holds back depends on the relationship between the oil pump absorption torque and the engine output torque. The engine does not hold back, indicating that the oil pump absorption torque is small and the engine load is light. If the working speed of the excavator is not obviously abnormal, the maximum output pressure of the main pump, that is, the system overflow pressure, should be checked in particular. If the overflow pressure measurement value is lower than the specified value, it indicates that the overload overflow valve setting value of the hydraulic circuit of the mechanism is incorrect, resulting in premature overflow of the mechanism and powerlessness. The machine can be adjusted by turning the adjustment screw.

②, digging powerlessness, engine holding back. The engine holding back indicates that the absorption torque of the oil pump is greater than the engine output torque, causing the engine to overload. This fault should first check whether the engine speed sensing system is normal, and the inspection method is similar to the engine inspection method described above. After the above detailed inspection and troubleshooting, the engine speed sensing system will resume normal function, the engine stalling phenomenon will disappear, and the digging force will return to normal.

What are the common reasons for the hydraulic pump not working?

The reasons for not working include power supply problems, low hydraulic oil level, filter blockage, hydraulic line leakage and pump internal component failure.

If you have any questions or concern, please contact us.

Excavator Spare Parts 21N8-20505 Switch Membrane For Hyundai R210LC-7

Excavator Parts 31N6-25130 Solenoid Valve For Hyundai R160LC-7

Excavator Spare Parts YB60000571 Pilot Valve For Hitachi ZX60

Excavator Spare Parts 8-98197654-0 Front Shock Absorber For ISUZU

Excavator Spare Parts 14714208 Control Valve For Volvo EC220E

Excavator Parts 5659737 Hydraulic Pump For Caterpillar 336GC

Bulldozer Hydraulic Main Control Valve 723-63-24100 For Komatsu D65-15

D31 Bulldozer Hydraulic Pump Ass'y 720-2M-00031 For Komatsu D31EX-21

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs