Kyotechs ISM11 Wiring Harness - Enhance Engine Performance

Kyotechs ISM11 Wiring Harness: Reliable Performance for Your Engine's Needs

Introducing the Kyotechs ISM11 Wiring Harness, a product designed with precision and durability in mind to enhance your engine’s performance. Ideal for ISM11 engines, this advanced wiring harness is specially crafted to ensure seamless connectivity and optimal functionality. Whether you are replacing an old harness or setting up a new engine, Kyotechs provides you with a solution that truly understands your needs.

Efficiency and Durability

The Kyotechs ISM11 Wiring Harness is renowned for its robust construction and reliable performance. Built from high-quality materials, it is designed to withstand extreme conditions, ensuring your engine operates smoothly and efficiently. This wiring harness promises to deliver consistent power, minimizing any disruptions in your engine’s operation. By choosing Kyotechs, you are investing in a product that reinforces your engine's reliability, reducing downtime and maintenance needs.

Precision Engineering and Compatibility

The Kyotechs ISM11 Wiring Harness is engineered with precision, adhering to high standards to guarantee compatibility with the ISM11 engine. This attention to detail in design and craftsmanship offers you a hassle-free installation process. Each component is meticulously crafted to fit perfectly within your engine system, ensuring no room for error that could cause performance issues.

Enhanced Performance

Kyotechs understands the importance of optimal engine performance, which is why the ISM11 Wiring Harness is designed to enhance your engine’s efficiency and longevity. By ensuring secure and stable connections, this wiring harness contributes significantly to improved engine performance, delivering the power and reliability you need when you need it.

User-Friendly Installation

Understanding the value of your time, Kyotechs has designed the ISM11 Wiring Harness for ease of installation. Even if you are not a seasoned mechanic, the straightforward setup process allows you to get your engine up and running without any hassle. Detailed instructions accompany each purchase, ensuring you can fit the harness securely and efficiently.

Customer-Centric and Reliable

Kyotechs values you as a customer and understands your need for reliable products. With the ISM11 Wiring Harness, you get the complete support of a brand committed to customer satisfaction and top-tier performance. Every product undergoes strict quality checks to ensure you receive a product that performs exceptionally well every time.

Experience the Kyotechs Difference

When you choose the Kyotechs ISM11 Wiring Harness, you are choosing a product that stands for quality, performance, and precision. Don’t just meet your engine needs—exceed them with a wiring harness that keeps your engines performing at their peak. At Kyotechs, we are dedicated to delivering products that not only enhance functionality but also enhance your overall experience.

Upgrade to a Kyotechs ISM11 Wiring Harness today and experience the seamless performance and reliability you deserve. Trust Kyotechs to care for your engine so you can focus on the journey ahead.

Detailed display

Advantages

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

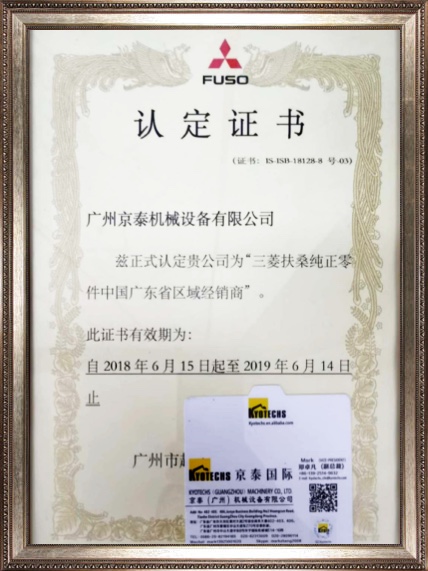

Qualification Certificate

MITSUBISHI FUSO

HANDOK Hydraulic

Cummins BETT & INSITE

Question you may concern

How to troubleshoot the excavator's swing system?

Swing system issues are usually related to the hydraulic motor, swing gears, or control valves. First, check the operation of the hydraulic motor, inspect the gears for wear, and ensure the control valves are working properly. Replace faulty parts as needed.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

How to check whether the hydraulic pump is leaking?

Ways to check whether the hydraulic pump is leaking include visually checking whether there is oil around the pump, checking the connections and seals for damage.

How do you know if the perpendicularity between the ground gear plane and the bearing hole has changed?

It can only be found when assembling the gear pump, because the end face clearance is very small, generally around 0.05mm. If the perpendicularity between the end face and the bearing hole has changed, the gear shaft cannot move after the pump is assembled. If the locking screw is loosened a little, but it still does not turn smoothly, and the gear pump is disassembled and inspected, there are scratches on the end face. This is caused by the end face plane not being perpendicular to the bearing hole.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs