Kyotechs R210-7 Engine: Efficient & Reliable Power for Heavy Machinery

Kyotechs R210-7 Engine: Powering Your Heavy Machinery with Precision and Reliability

Introducing the Kyotechs R210-7 Engine, a powerhouse designed to redefine efficiency and performance in heavy machinery. This advanced engine is the culmination of cutting-edge engineering and extensive industry expertise, making it the ideal choice for professionals who demand more from their equipment. The R210-7 is not just an engine; it is a commitment to empowering your operations with unmatched reliability, durability, and innovation.

Unparalleled Performance and Efficiency

The Kyotechs R210-7 Engine is engineered for superior power output, ensuring your machinery operates at peak performance levels, even under the most demanding conditions. Its state-of-the-art design focuses on optimizing fuel consumption, helping you to reduce operational costs without compromising on power or speed. Whether you’re in construction, mining, or forestry, the R210-7 effortlessly adapts to various applications, providing consistent and robust performance that keeps your projects on track.

Innovative Technology for Enhanced Durability

What sets the Kyotechs R210-7 apart is its pioneering technology that enhances the engine’s lifespan and resilience. Built with high-quality materials and sophisticated manufacturing processes, this engine is designed to withstand extreme environments and rigorous usage. The advanced cooling system and reinforced structural components contribute to prolonged engine life, reducing downtime and maintenance costs—assets that are crucial to maximizing productivity in your operations.

Eco-Friendly Engineering

Kyotechs understands the importance of environmental responsibility, which is why the R210-7 Engine incorporates eco-friendly engineering practices. It features reduced emissions technology, ensuring compliance with global environmental standards while maintaining high performance. This conscious approach not only supports sustainability but also positions your business as a responsible participant in today’s increasingly eco-conscious marketplace.

Seamless Integration and User-Friendly Design

Ease of integration is one of the defining qualities of the Kyotechs R210-7 Engine. Its user-friendly design ensures that installation and operation are as seamless as possible, allowing you to quickly get your machinery up and running. The engine is compatible with a wide range of equipment, making it a versatile addition to your fleet. Additionally, the intuitive control systems and comprehensive support network provided by Kyotechs ensure that your team can efficiently maintain and operate the engine with confidence.

The Kyotechs Promise

Choosing the Kyotechs R210-7 Engine means investing in a brand dedicated to quality, performance, and customer satisfaction. Backed by a robust warranty and exceptional customer service, Kyotechs assures you that your investment is protected. This commitment to excellence and reliability is what makes the R210-7 Engine a leader in its class, providing you with the peace of mind and confidence needed to power forward.

Picture Show

Our Advantages

Tailored Services

We prioritize providing professional services, ensuring that our clients receive personalized attention and support, contributing to a positive and efficient business relationship.

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

Professional Parts Query Software

Our specialized parts query software streamlines and enhances the customer experience by providing an efficient process for searching for and identifying the exact components they need.

Expertise In Engine Components

Focusing on engine components adds a layer of specialization, making us a go-to source for clients seeking high-quality parts specifically for engines.

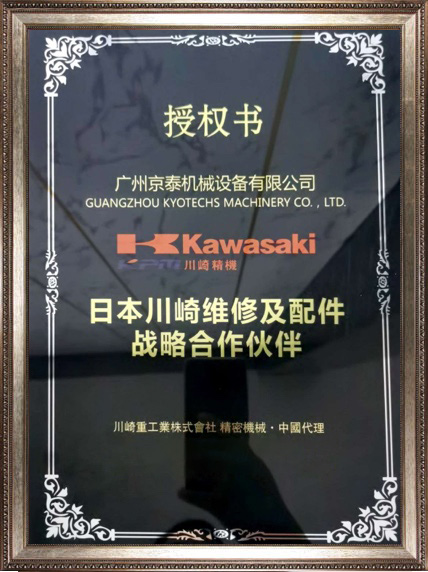

Qualification Certificate

TUV

SANY Power

KAWASAKI

Frequently Asked Questions

How to address electrical failures in hydraulic pumps?

Possible loose connections, damaged wiring, or sensor failure.

Solution: Tighten connections, repair wiring, replace faulty sensors.

What to do if the excavator has difficulty starting?

Check the battery charge and connections, inspect the starter motor and ignition system, ensure the fuel system is supplying fuel properly, and read fault codes for further diagnostics.

What should I pay attention to when assembling a gear pump?

The pump housing will wear more in the oil inlet chamber. If the pump housing is symmetrical, it can be turned 180 degrees. Then use it. For the passive gear, the two ends cannot be replaced. Make a mark when removing it. Because the gear will wear on one side. The active gear is integrated with the rotating shaft and cannot be turned over; turning the passive gear over can change the contact point of the meshing line of the two gears. After the pump is assembled, add a little lubricating oil and rotate it slightly by hand. The feel should be smooth.

How should Kobelco excavators be maintained in high temperatures in summer?

Kobelco excavator maintenance tips 1: Cooling to prevent air blockage In high temperatures in summer, the engine is prone to air blockage due to high speed and difficult heat dissipation, which makes it difficult to start the engine after stopping for a few minutes. Once air blockage occurs, the excavator driver should stop the engine immediately to cool down and eliminate the fault.

Kobelco excavator maintenance tips 2: Observe the water temperature gauge at any time to prevent water shortage When driving in high temperature weather, always pay attention to checking the cooling water volume and the water temperature gauge. When water shortage is found, immediately idle the engine to cool down before adding water, and be careful not to open the radiator cap immediately to prevent burns.

Kobelco excavator maintenance tips 3: Prevent engine oil from deterioration Lubricating oil is easily diluted by heat, resulting in poor oxidation resistance, easy deterioration, and even causing faults such as burning of the bearing and the shaft. Therefore, the crankcase and gearbox should be replaced with summer lubricating oil, and the amount and quality of the lubricating oil should be checked frequently, and replaced in time.

Kobelco excavator summer maintenance tips 4: timely cleaning of engine surface oil If the external oil of the engine is too thick, it will affect the heat dissipation and bury the hidden danger of failure of various parts. You can use the high-pressure spray method to clean the engine parts with a cleaning agent that does not corrode the body parts.

Kobelco excavator summer maintenance tips 5: prevent the water tank water temperature from being too high In summer, the cooling water of Kobelco excavators evaporates and consumes quickly. You must add enough cooling water before leaving the vehicle, and check the water level frequently during work. For single-cylinder diesel engines without a water temperature gauge, always pay attention to the red mark height of the water tank float. If the float cannot be used normally, it should be repaired in time. If the boiling phenomenon occurs during work, do not add cooling water directly. Stop the work, slow down the generator, and slowly add cooling water after the water temperature drops to avoid cracks in the water tank when it is cold.

Kobelco excavator summer maintenance tips 6: Ensure the best oil supply time In summer, the oil supply time of Kobelco excavators should be adjusted. If the oil is supplied too early, the engine will make a knocking sound and sometimes reverse; the oil supply time should not be too late, otherwise the engine will work weakly.

If you have any questions about our goods or services, please feel free to contact us.

Excavator Spare Parts 21N8-20505 Switch Membrane For Hyundai R210LC-7

Excavator Parts 31N6-25130 Solenoid Valve For Hyundai R160LC-7

Excavator Spare Parts YB60000571 Pilot Valve For Hitachi ZX60

Excavator Spare Parts 8-98197654-0 Front Shock Absorber For ISUZU

Excavator Spare Parts 14714208 Control Valve For Volvo EC220E

Excavator Parts 5659737 Hydraulic Pump For Caterpillar 336GC

Bulldozer Hydraulic Main Control Valve 723-63-24100 For Komatsu D65-15

D31 Bulldozer Hydraulic Pump Ass'y 720-2M-00031 For Komatsu D31EX-21

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs