Kyotechs SK200-8 Turbocharger: Superior Efficiency and Reliability

Kyotechs SK200-8 Turbocharger: Enhanced Performance and Reliability

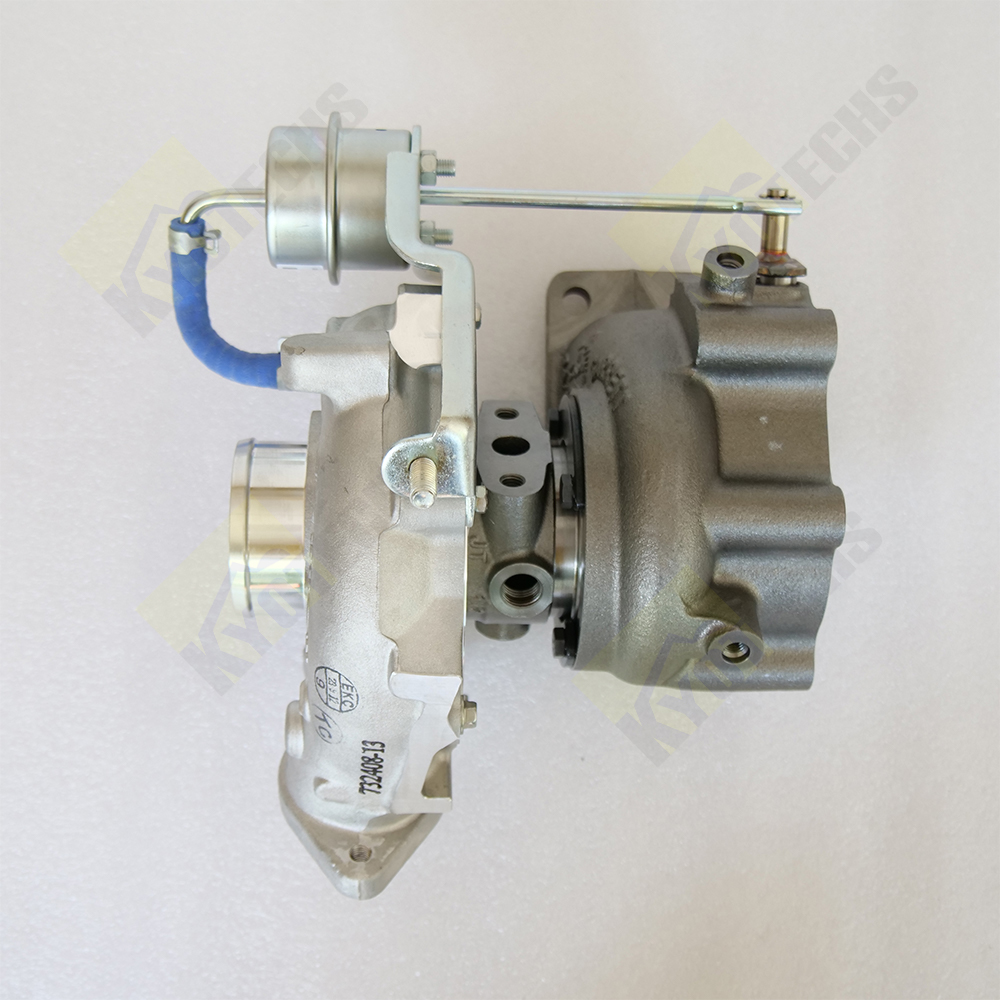

Introducing the Kyotechs SK200-8 Turbocharger, a game-changer engineered for unparalleled performance and durability. Specially designed for heavy-duty machinery, this turbocharger enhances engine efficiency, providing increased horsepower and improved fuel economy for your equipment.

Featuring high-quality construction and precision engineering, the Kyotechs SK200-8 Turbocharger promises remarkable dependability and longevity. Its advanced design enables optimal air compression, reducing engine lag and delivering smoother power transitions. This makes it an ideal choice for those in construction, mining, or any industry where machinery reliability is non-negotiable.

Installation is straightforward, with all necessary components included, ensuring a hassle-free setup. This turbocharger is meticulously crafted to fit perfectly, minimizing downtime and maximizing productivity. Kyotechs prioritizes customer satisfaction, embedding quality at every step to ensure that every SK200-8 Turbocharger meets rigorous standards.

Customers rave about the noticeable performance improvements and cost efficiency, making it a top choice for professionals seeking real value. Moreover, with Kyotechs, you can expect exceptional customer support that ensures your needs are met promptly and professionally.

Embrace the power of the Kyotechs SK200-8 Turbocharger and experience the difference in performance and reliability. Your machinery deserves the best, and with Kyotechs, you receive innovation, practicality, and value in one solid package.

Product Image

Advantages

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Global Reach

Engaging in global accessory supply positions us as a global player, allowing customers from different parts of the world to access our specialized services and products.

One-Stop Hydraulic Repair Solution

Kyotechs presents a comprehensive "One-Stop Hydraulic Repair Solution," equipped with a professional hydraulic maintenance team and cutting-edge testing machines.

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

Our Certifications

Tongmyung

SANY Power

WYS

Q&A

How to handle hydraulic pump pressure fluctuations?

Possible air in the system, clogged filter, or worn pressure relief valve.

Solution: Bleed air from the system, clean or replace filter, replace pressure relief valve.

How to avoid the derailment (chaining) of the crawler chain of the excavator?

1. When walking on the construction site, please try to place the travel motor behind the walking to reduce the squeezing of the sprocket.

2. The continuous walking time of the machine cannot exceed 2 hours. The walking time on the construction site should be minimized. If necessary, it is recommended to walk after a short stop in the middle.

3. Avoid raised hard objects when walking to avoid stress concentration on the track chain.

4. Confirm the tightness of the crawler, adjust the crawler tighter in soft places such as soil, and adjust the crawler looser when walking on stones. It is not good to have a crawler that is too loose or too tight. Too loose will cause the crawler to derail easily, and too tight will cause the chain sleeve to wear too quickly.

5. Check whether there are foreign objects such as stones in the crawler frequently, and clean them if there are.

6. When working on a muddy construction site, it is necessary to frequently idle to discharge the soil deposited in the crawler.

7. Try to avoid the excavator turning in circles on the spot.

8. Regularly check the rail guard and the rail guard welded under the guide wheel.

How to prevent hydraulic pump failure?

The way to prevent hydraulic pump failure includes regular maintenance, keeping the hydraulic oil clean, regularly changing filters, and avoiding overload operation.

What to do if the excavator has an oil leak?

To address oil leaks, inspect seals, fittings, and lines. Locate the leak, tighten any loose fittings, and replace worn or damaged seals and lines. Clean the area and recheck for leaks.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs