Kyotechs ZX210-5B Cylinder Head - Performance and Reliability

Introducing the Kyotechs ZX210-5B Cylinder Head – the solution for enhancing the performance and longevity of your machinery. Precision-crafted and rigorously tested, this cylinder head ensures seamless compatibility and unparalleled reliability, making it the gold standard for replacement parts in the industry.

The Kyotechs ZX210-5B Cylinder Head is engineered with the finest materials, delivering robust durability and superior heat resistance. It’s meticulously designed to fit flawlessly, ensuring optimal engine efficiency and consistent power output. Whether you’re in construction, agriculture, or any heavy-duty industry, this cylinder head is your trusted partner in keeping operations smooth and uninterrupted.

Our commitment to quality and excellence is reflected in every inch of the ZX210-5B Cylinder Head. Kyotechs employs advanced manufacturing techniques and adheres to stringent quality control measures to bring you a product that exceeds expectations. Enjoy peace of mind knowing that your equipment is supported by a component known for its reliability and enhanced performance.

Additionally, installation is straightforward and hassle-free, backed by comprehensive technical support and service from Kyotechs, ensuring you receive professional assistance whenever needed. Upgrade your machinery with the Kyotechs ZX210-5B Cylinder Head and experience a blend of innovation, dependability, and exceptional performance.

Detailed display

Advantages

Covering a wide array of brands makes us a one-stop solution for clients, offering a comprehensive range of components for various types of machinery, which can be a significant competitive advantage.

One-Stop Engine Repair Solution

Kyotechs presents a comprehensive "One-Stop Engine Repair Solution" designed to address a variety of engine repair needs.

Diverse Brand Specialization

We cater to a wide range of renowned brands such as Caterpillar, Cummins, Hyundai, Doosan, Hitachi, JCB, CASE Construction, CNH, Kobelco, Komatsu, and Volvo, showcasing our comprehensive understanding of the industry.

Reliable Brands

Kyotechs dealing with reputable brands in the industry signifies our commitment to offering reliable and top-notch products, instilling confidence in our customers regarding the quality of the components they purchase.

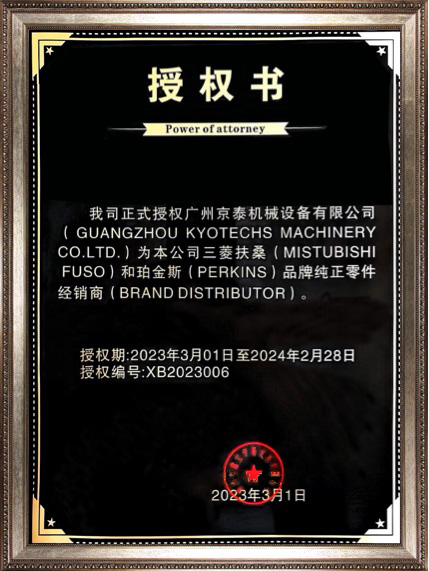

Our Certifications

Perkins

SANY Power

HANDOK Hydraulic

Frequently Asked Questions

When does the battery in use need to be recharged?

When the battery liquid specific gravity is lower than 1.15 or the single cell voltage is lower than 1.7V (V), or when changing seasons for maintenance, it should be removed for recharging and the liquid specific gravity should be adjusted. If it needs to be parked for a long time, it should be fully charged and stored, and recharged once a month. If it needs to be stored for a long time, it should be fully charged, all the liquid should be poured out, and the filling port should be sealed for storage. When it needs to be used, re-add the electrolyte that meets the requirements.

What are the conditions for good starting performance of excavators?

- There must be enough starting speed. The high starting speed means less gas leakage in the cylinder, shorter heat transfer time of compressed air to the cylinder wall, less heat loss, and higher gas temperature and pressure at the end of compression. Generally, the speed is required to be above 100r/min.

2. The cylinder should have good sealing. This can further reduce the amount of leakage and ensure that the gas has sufficient combustion temperature and pressure at the end of compression. The compression pressure of the cylinder shall not be lower than 8_0_%_ of the standard value.

3. The engine is required to have appropriate clearance relative to the running parts and good lubrication.

4. The battery must have sufficient starting capacity and the technical condition of the starting circuit is normal.

5. The starting oil volume meets the requirements, the injection quality is good, and the injection advance angle meets the requirements.

6. Use fuel that meets the requirements

What causes abnormal noise from the hydraulic pump during operation?

Possible air in the system, cavitation, internal component wear, or oil contamination. Solution: Bleed air from the system, check and fix cavitation sources, replace worn components, replace hydraulic oil.

What is the cause of hydraulic system overheating?

Causes of overheating may include low hydraulic oil level, clogged filter, excessive system load or cooling system failure.

Excavator Parts 340-3466 Control Valve For Caterpillar M313D M315D2

Excavator Parts 235-60-11100 Hydraulic Pump For Komatsu GD805 GD825

Excavator Spare Parts 153-9624 Hydraulic Main Pump For Caterpillar CAT988H

Excavator Parts ND116140-0050 Core Ass'y Heater For Komatsu PC200-8

Excavator Parts Drier Assy-Receiver 11N6-90060 Drying Bottle For Hyundai R215-7

Excavator Parts 8N-7005 170-5183 Fuel Injector For Caterpillar CAT 3304

Excavator Parts 31N7-10010 Hydraulic Main Pump K3V112DT-9N3P For Hyundai R215-7

Excavator Parts 31N6-10210 Swing Motor JMF151 For Hyundai R210-7 R215-7 R220-5 R225-7

To be a happy enterprise in the field of engineering equipment.

Kyotechs delivers efficient and reliable service at each stage to meet the customer's needs.

Contact

Contact: Ally Fan

Email: kyotechs@kyotechs.com

Tel: +86 020 - 82313009

Skype: allyfan333

Mobile / Whatsapp / Wechat:

+86 - 18826315313

Address: 268 Zhongshan Avenue East, Guangzhou, Guangdong, China.

© 2024 KYOTECHS. All Rights Reserved. Designed by gooeyun

Kyotechs

Kyotechs GZ

Kyotechs

Kyotechs